Have you ever wondered why car batteries seem to cost a small fortune these days? If you’ve ever found yourself facing a hefty bill at the mechanic, you’re not alone. Car batteries are essential for starting your engine, but they aren’t exactly cheap. In this article, we’ll break down exactly why car batteries cost what they do, from the materials used to the manufacturing process, and everything in between.

The Materials Behind the Price: Why Do Car Batteries Cost So Much?

You’ve probably noticed that car batteries can vary significantly in price, ranging from affordable to downright expensive. So what exactly is driving these costs up? Well, one of the biggest factors is the materials used to make these batteries. Let’s break this down and see what exactly goes into a car battery.

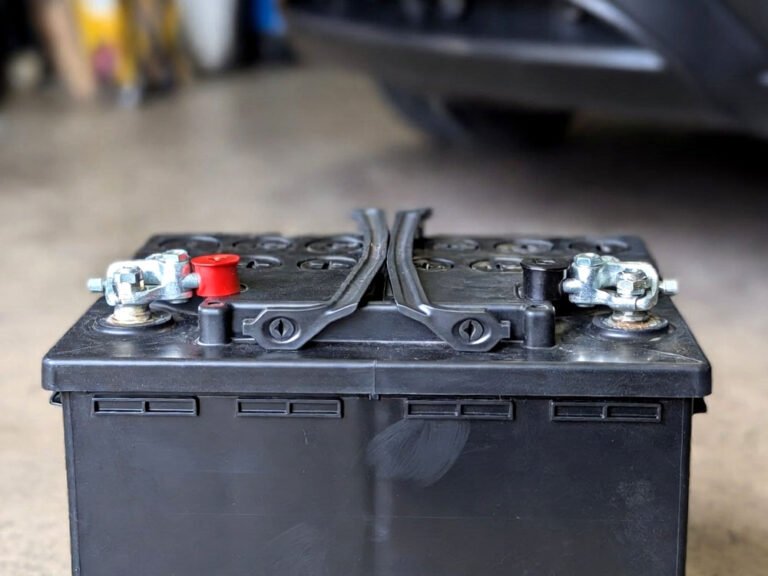

Lead, Acid, and the Cost of Materials

The traditional car battery is known as a lead-acid battery, and its cost can be largely attributed to the materials used. Lead is a heavy metal, and its extraction, processing, and refinement are all expensive processes. Add to that the sulfuric acid required to create the battery’s chemical reactions, and you’ve got the foundation for a costly item.

You might be wondering: “But isn’t lead a common material?” The answer is yes, but getting high-quality, pure lead and sulfuric acid is still costly due to the amount of energy required to refine and process these materials. Mining for lead isn’t cheap either, and it’s only getting more expensive due to increasing regulations around mining and environmental concerns.

The Rise of Lithium-Ion Batteries

In recent years, there has been a shift toward lithium-ion batteries, especially in electric vehicles (EVs). These batteries are different from the traditional lead-acid batteries that most gas-powered cars use. Lithium-ion batteries are made from a combination of lithium, cobalt, nickel, and other rare earth metals.

Why is this a big deal? Lithium-ion batteries, while more efficient and longer-lasting than lead-acid batteries, are much more expensive to produce. The prices of materials like lithium and cobalt have skyrocketed in recent years due to their increasing demand. As electric vehicles (EVs) become more popular, the demand for these rare materials only increases, which can raise the price of car batteries across the board.

Moreover, the extraction of lithium and cobalt comes with its own set of challenges. These materials are often mined in countries where regulations and safety standards may not be as strict, and labor conditions can be questionable. This can affect the overall cost of the materials, adding to the final price of the battery.

Supply Chain Issues and Shipping Costs

In today’s global economy, many car batteries—especially those for electric vehicles—are sourced from all over the world. Lithium, cobalt, and other rare metals often come from far-flung corners of the globe, including South America, Africa, and China. With the increasing demand for these materials, the transportation and logistics of getting them to the factory become more expensive.

Shipping costs have also been affected by global trade disruptions, especially in recent years. Issues like supply chain bottlenecks, rising fuel costs, and labor shortages all play a role in pushing prices up. Add in the fact that batteries are heavy and require careful handling, and it’s easy to see how shipping costs add up.

Manufacturing and Technological Factors: Why It’s Not Just About the Materials

It’s not just the raw materials that affect the cost of a car battery. The process of manufacturing these batteries is both intricate and costly. Let’s take a closer look at how the manufacturing process and technological advancements can drive up prices.

Advanced Technology and Safety Standards

Manufacturing a car battery is not a simple task. It requires highly specialized equipment, skilled labor, and rigorous safety protocols. Car batteries must be built to withstand extreme temperatures, vibrations, and potential leaks. This means that battery manufacturers must adhere to strict safety standards, which can increase production costs.

For instance, to ensure the battery’s safety, manufacturers often integrate advanced technology like temperature sensors, electronic control units, and safety valves. These add additional costs to the final product. Furthermore, the technology used in the production of electric vehicle batteries is more advanced, which requires even more specialized equipment and expertise.

Quality Control and Testing

Once a car battery is manufactured, it goes through extensive testing to ensure its reliability. Batteries need to undergo rigorous quality control checks to ensure they meet industry standards. Tests are done to evaluate the battery’s performance, longevity, and safety features, and this process requires time, labor, and additional materials.

Given that car batteries are essential to the functioning of a vehicle, manufacturers must ensure that they can handle a wide range of conditions, from extreme heat and cold to long-term usage. This level of testing and quality assurance adds significant costs to the production process.

Innovation in Battery Life and Efficiency

Another factor pushing up battery prices is the continuous research and development efforts aimed at improving battery efficiency and lifespan. Manufacturers are constantly looking for ways to extend battery life, reduce charging times, and increase overall efficiency. While these innovations are great for consumers in the long run, they come with an upfront cost.

For example, in electric vehicle batteries, advances like solid-state batteries, which promise to offer even better energy density and safety, are in development. These newer technologies are still in the early stages, but they require significant investment in research and development, which contributes to the higher prices of new car batteries.

Economies of Scale and Supply and Demand

With the growing popularity of electric vehicles, the automotive industry is seeing a major shift in demand for car batteries. As more people adopt electric vehicles, manufacturers are working hard to scale up production. However, achieving economies of scale—where the cost per unit decreases as production increases—can take time. It’s a balancing act, and in the meantime, consumers are left to bear the higher costs associated with scaling up production.

Additionally, the demand for car batteries is growing faster than the supply. As governments around the world push for greener, more sustainable transportation, more and more consumers are making the switch to electric vehicles. This surge in demand has put pressure on battery manufacturers, leading to higher prices as they scramble to meet the need.

Factors Beyond the Battery: What Else Makes Car Batteries Expensive?

While the materials and manufacturing processes play a significant role in the high cost of car batteries, other factors also contribute to the hefty price tag. Let’s take a closer look at a few external influences that impact the overall price.

Environmental and Regulatory Costs

In the modern world, environmental sustainability is a major concern, and this is true for the automotive industry as well. Regulations surrounding the extraction and disposal of materials used in car batteries are becoming stricter. Governments are imposing regulations to limit the environmental impact of mining for materials like lead, lithium, and cobalt.

Battery manufacturers are also under pressure to find more sustainable ways to produce and dispose of batteries. This includes reducing the environmental impact of the manufacturing process, improving battery recycling programs, and finding alternative materials that are less harmful to the environment. While these initiatives are important for the planet, they also come with added costs that are ultimately passed on to the consumer.

The Role of Brand and Warranty

Just like with any other product, the brand of car battery you choose can also affect the price. Premium battery brands that offer longer warranties and better performance often come with a higher price tag. These brands usually provide higher-quality products that are designed to last longer, which can justify the additional cost.

Additionally, the warranty associated with a car battery is often a significant factor in its price. A battery with a longer warranty, which typically guarantees performance for several years, will cost more upfront. However, the peace of mind that comes with this warranty can be worth the extra cost in the long run.

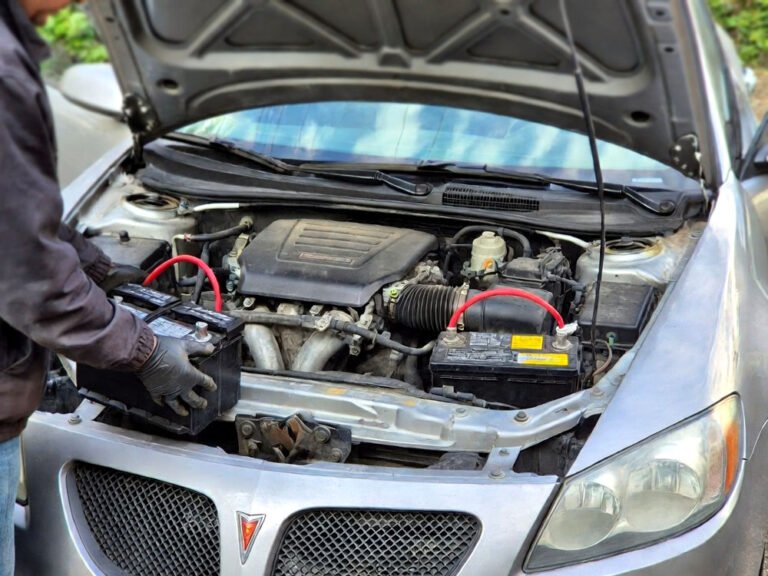

Labor and Technicians

Finally, labor costs play a role in the overall price of car batteries, especially when it comes to installation. If you’ve ever had a battery replaced, you know that labor charges can add a significant amount to the final price. Professional technicians who install car batteries need to be highly skilled, and their labor is often priced accordingly. In some cases, the cost of the battery itself is just a small part of the total expense, with labor charges pushing the final bill much higher.

I Hope You Now Understand Why Car Batteries Are Expensive

Understanding why car batteries are so expensive requires taking a closer look at the materials, manufacturing processes, and external factors involved. From the raw materials to the technology and testing, there are many moving parts that contribute to the overall cost. Whether you’re looking at a traditional lead-acid battery or a cutting-edge lithium-ion battery, the complexity and demand for these essential components drive prices up. While it may be a bit of a shock to the wallet, now you know what goes into making sure your car starts every time!

Are These Questions on Your Mind?

Is it cheaper to replace a battery yourself?

Replacing a car battery yourself can save you the cost of labor, but it’s important to consider whether you have the necessary skills and tools to do the job safely.

Can I use a non-brand battery in my car?

Yes, but using a non-brand battery may affect the performance of your vehicle and might void your warranty.

Do I need to replace my car battery every 3 years?

Most car batteries last between 3 to 5 years, but this can vary depending on your car’s usage and environmental factors.

Is it true that electric car batteries are much more expensive?

Yes, electric car batteries are more expensive due to the rare materials used and the technology involved, but they last much longer than traditional batteries.

Can my car’s battery be recycled?

Yes, car batteries can be recycled, and many recycling programs exist to help reduce environmental impact.

Do I have to buy a new battery if my car won’t start?

Not necessarily. Sometimes a dead battery can be recharged or revived, but if it’s old, it may need replacing.

Is it harmful to dispose of a car battery incorrectly?

Yes, improper disposal of car batteries can harm the environment due to the toxic chemicals and metals inside.

Can weather affect the life of a car battery?

Yes, extreme temperatures—especially cold—can shorten the lifespan of a battery, making regular checks important.

Do hybrid cars need special batteries?

Yes, hybrid cars use specialized batteries that can be more expensive than traditional ones.

Is the cost of car batteries expected to decrease in the future?

While battery prices may decrease as technology improves and production scales up, the rising demand for electric vehicles could keep prices higher in the near term.