Picture this: you’re cruising down the road, music humming, when suddenly your brakes squeal like a horror movie soundtrack. That’s the moment most of us realize it’s time to change the brake pads. I remember staring at my car one rainy evening, shivering, wondering what tools I even needed to get started. It felt overwhelming until I discovered that with the right set of tools, patience, and a bit of elbow grease, changing brake pads is actually satisfying and doable. Let’s dive into everything you need so you can tackle this project like a pro.

First, gather essential tools: a reliable jack and jack stands for safety, a lug wrench to remove wheels, and a C-clamp or brake caliper tool to compress calipers. Add a socket set, ratchet, and wrench set to remove caliper bolts. Keep a flathead screwdriver or pry bar for gently nudging parts, gloves to protect your hands, and brake cleaner to remove grime. Finally, have your new brake pads ready along with a torque wrench to tighten bolts accurately.

Safety First: Setting Up Your Workspace

Before touching a single bolt, creating a safe and organized workspace is critical. I learned this the hard way the first time I jacked up a car on uneven ground. A solid, flat surface ensures your jack and stands won’t slip. Always use jack stands after lifting the car; never rely solely on a jack. It might seem tedious, but your safety is non-negotiable. Wearing gloves and safety glasses is another small step that saves you from painful scrapes and dust in your eyes.

Good lighting makes a huge difference. I used to struggle finding bolts until I installed a small LED work lamp. Clear workspace prevents accidents, and keeping tools nearby avoids constant bending and scrambling. Laying down old towels or a mechanic mat under the wheels also helps catch dirt or oil. It’s not glamorous, but when everything is ready and visible, the process feels smoother and less stressful.

Organizing tools in advance prevents frustration mid-job. Imagine loosening a stubborn caliper bolt and realizing your wrench is stuck in the garage. Keeping a dedicated toolbox with labeled compartments for sockets, screwdrivers, and brake-specific tools makes a huge difference. You’ll thank yourself later when you move fluid-free and stress-free from one task to the next.

- Flat, stable surface is essential

- Always use jack stands

- Gloves, glasses, and proper lighting prevent accidents

- Organize tools for efficiency

Removing Wheels and Inspecting Components

Once your car is securely lifted, it’s time to remove the wheels. I always start with the lug wrench to loosen bolts slightly while the car is still on the ground. It saves energy and prevents the wheel from spinning mid-loosening. After jacking the car, remove the wheels fully and set them aside on a clean surface. This is also a perfect moment to inspect the tires, rotors, and suspension.

When I first looked closely at the rotors, I noticed grooves I had ignored for months. Brake pads are easier to replace if you know exactly what you’re dealing with. Check the rotor surface for wear and debris. Sometimes the pads are fine, but the rotors might need resurfacing or replacement. If they are worn unevenly, skipping this step can lead to a noisy, shaky brake job later.

Take your time handling calipers and bolts. I once stripped a caliper bolt because I rushed with the wrong socket size. Double-checking fit and gently loosening each bolt avoids damage. Keep a magnetic tray handy for bolts and clips so nothing vanishes under the car. These small steps make the job faster and far less frustrating than chasing fallen hardware.

- Loosen lug nuts before jacking

- Inspect tires, rotors, and suspension

- Use correct socket sizes

- Keep bolts organized

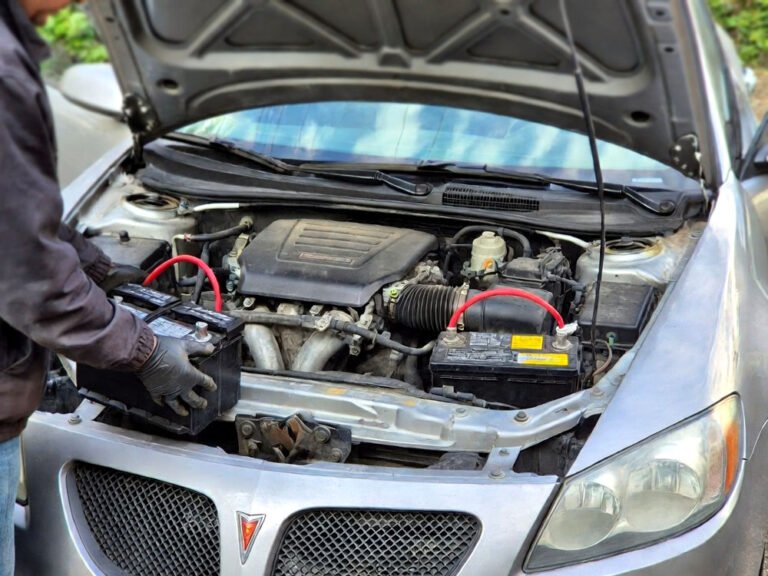

Tools to Compress the Brake Caliper

One of the trickiest moments for beginners is compressing the brake caliper. When I started, I tried it with bare hands and almost ruined the pads. The right tool makes all the difference. A C-clamp works well on most cars; you place it over the caliper and slowly squeeze until the piston retracts. Some cars require a specific brake caliper tool that twists the piston back instead of pushing straight in.

Using the right technique is key. I learned that going too fast risks cracking the piston or damaging seals. Apply brake cleaner first to remove grime around the piston; it glides smoother and reduces risk. Always compress slowly and evenly, checking alignment frequently. You’ll notice resistance at first, then a smooth push as the piston slides back into the caliper.

It’s also smart to check for leaks or fluid buildup while compressing. A tiny drop of brake fluid on the rim or rotor can be wiped immediately, preventing staining or corrosion. A small rag or shop towels make cleanup easy. Taking a few extra minutes here avoids big headaches when reassembling everything.

- Use a C-clamp or caliper tool

- Compress slowly to protect seals

- Clean piston with brake cleaner

- Monitor for leaks during compression

Installing New Brake Pads

Now comes the fun part: sliding in your new pads. I remember the satisfying click the first time a new pad snapped perfectly into the caliper bracket. Make sure the friction surface faces the rotor and that any anti-rattle clips are correctly seated. Improper installation is noisy and can reduce braking efficiency.

Grease the contact points lightly to prevent squeaking. I use high-temp brake grease sparingly; too much can melt onto the rotor and cause smoking, so moderation is key. Slide the caliper over the new pads carefully, ensuring the piston doesn’t bind. If it’s tight, double-check that the piston is fully compressed.

After installation, spin the rotor by hand to make sure it moves freely. Listen for rubbing or uneven contact; if anything feels off, it’s easier to correct now than after driving. Reattaching bolts with a torque wrench ensures they are neither too loose nor over-tightened, avoiding stripped threads and maintaining safety.

- Pad friction faces rotor

- Use anti-squeal grease sparingly

- Caliper slides without binding

- Torque bolts to specification

Testing and Adjusting Brakes

Once everything is reassembled, testing the brakes before hitting the road is crucial. Press the brake pedal several times to seat the new pads against the rotor. You’ll feel the pedal firm up as the pistons adjust. This step prevents spongy braking and ensures immediate response. I always check fluid levels while pressing the pedal, topping up if needed.

Next, perform a slow, short test drive in a safe area. Listen for squeaks, grinding, or vibrations. If you notice unusual sounds, stop immediately and inspect. Small adjustments, like tightening caliper bolts or checking pad alignment, are easier now than later. A friend once ignored minor rubbing, which led to rotor damage; learning from mistakes is invaluable.

Remember that new pads require a short break-in period. Gentle braking for the first 100 miles helps transfer material evenly to the rotor and ensures long-term performance. The difference is noticeable: smooth, confident stops without noise or vibration.

- Press brake pedal to seat pads

- Check brake fluid levels

- Perform cautious test drive

- Follow break-in period

Cleaning and Maintaining Tools

After the brake job, cleaning your tools and workspace is often overlooked but important. Brake dust and grime are corrosive; leaving them on sockets or wrenches shortens their lifespan. I usually spray tools with a light degreaser and wipe them thoroughly. Keeping them in a dedicated toolbox prevents rust and keeps your next project stress-free.

Rags, old towels, and brake cleaner help remove dust from the surrounding area. I’ve learned that even a tiny layer of dust under the car can spread into the garage. Take a few minutes to sweep, organize, and check your toolkit. You’ll feel more prepared and confident for the next maintenance task.

Proper maintenance of brake components is also key. Store leftover pads or hardware in labeled containers. It avoids confusion and ensures you always have spares ready. Caring for tools and parts isn’t glamorous, but it’s what makes DIY work enjoyable, safe, and efficient.

- Clean tools immediately after use

- Remove brake dust from workspace

- Organize leftover parts

- Store tools properly for longevity

| Action | Tool Needed | Tips & Notes |

|---|---|---|

| Lift the car | Hydraulic jack, jack stands | Always on a flat surface, never rely only on the jack |

| Loosen lug nuts | Lug wrench | Loosen before jacking the car up |

| Remove caliper bolts | Socket set, ratchet | Keep bolts in a magnetic tray |

| Compress caliper piston | C-clamp or caliper tool | Compress slowly, clean with brake cleaner |

| Remove old pads | Flathead screwdriver | Pry gently, avoid damaging caliper |

| Install new pads | Gloves, high-temp grease | Grease contact points lightly |

| Reassemble caliper | Torque wrench | Tighten bolts to manufacturer specs |

| Test brakes | None | Press pedal repeatedly, short test drive |

Final Thoughts

Changing brake pads may seem intimidating at first, but with the right tools and a careful approach, it’s incredibly rewarding. Each step, from safely lifting your car to testing brakes, builds confidence and keeps you in control. Take your time, organize your tools, and enjoy the satisfaction of hearing that smooth, confident stop. Your car—and your wallet—will thank you.

Frequently Asked Questions (FAQs)

Is it safe to change brake pads at home?

Yes, it can be very safe if you follow proper precautions. Always work on a flat, stable surface and use jack stands after lifting the car. Wear gloves and safety glasses to protect hands and eyes from dirt, dust, and chemicals. Take your time, follow torque specs for bolts, and double-check all components. Many DIYers successfully change brake pads at home, and with careful attention, it’s safe and cost-effective.

Can I use any C-clamp to compress the caliper?

Most standard C-clamps work, but some vehicles need a specific brake caliper tool to rotate the piston back instead of pushing it straight. Using a regular C-clamp is fine for simple pistons, but if it feels too tight or resists, check the manufacturer’s guide. Always compress slowly to avoid damaging seals or pistons. Cleaning the piston with brake cleaner before compressing helps it slide smoothly and prevents sticking.

Do I need special grease for brake pads?

Yes, using high-temperature brake grease is recommended for contact points where pads touch calipers or brackets. This reduces squeaks and ensures smooth movement. Apply a thin layer only; too much grease can melt onto the rotor when braking and cause smoke or noise. Never lubricate the friction surface of the pads themselves, as it compromises braking safety.

Is it necessary to replace rotors when changing pads?

Not always, but it’s worth inspecting them. Rotors with deep grooves, warping, or uneven wear can reduce braking performance even with new pads. Light surface wear is usually fine, but if you notice vibrations or noise, resurfacing or replacing rotors is recommended. Checking rotors while removing wheels makes the process easier and prevents future problems.

Can I drive immediately after installing new pads?

You should perform a short, cautious test drive first. Press the brake pedal several times before moving to seat the pads against the rotor. Then drive slowly in a safe area, listening for squeaks, grinding, or vibrations. New pads also need a gentle break-in period, usually around 100 miles, to transfer material evenly to the rotors and ensure optimal performance.

Do I need a torque wrench for this job?

Yes, a torque wrench is strongly recommended for caliper and wheel bolts. Tightening bolts too loosely risks components coming off, while over-tightening can strip threads or damage parts. Follow manufacturer torque specs precisely to ensure safety and maintain proper brake function.

Is it hard to organize tools for brake maintenance?

It’s not hard but requires planning. Keeping a toolbox with labeled compartments for sockets, wrenches, screwdrivers, and brake-specific tools prevents searching mid-job. A magnetic tray for small bolts helps keep track of hardware. Organizing your workspace reduces stress, prevents mistakes, and makes the job more enjoyable, especially for beginners.

Can brake cleaner replace soap and water for cleaning parts?

Brake cleaner is specifically formulated to remove brake dust, grease, and grime without leaving residue. Soap and water can remove dirt but often leave moisture, which may cause corrosion. Use brake cleaner on rotors, calipers, and surrounding areas for a safe, chemical-free clean. Always wipe off excess and avoid contact with painted surfaces.