You lean over the engine, socket on the plug, feeling confident. Then it happens. The spark plug turns, and turns, and turns. It never lifts. Your stomach sinks because now you know this job just got real. I have been there, knuckles greasy, heart racing, wondering if I just ruined my day or my engine.

Stop turning the spark plug once you feel endless spinning and avoid forcing it further, spray penetrating oil around the threads and let it soak patiently, gently pull upward on the socket while slowly turning to catch damaged threads, try tightening slightly before loosening again to reset thread alignment, use a magnet or spark plug boot to add upward tension, inspect for stripped threads or broken plugs once removed, and prepare for thread repair tools if resistance never changes.

Why a Spark Plug Won’t Come Out Just Keeps Spinning

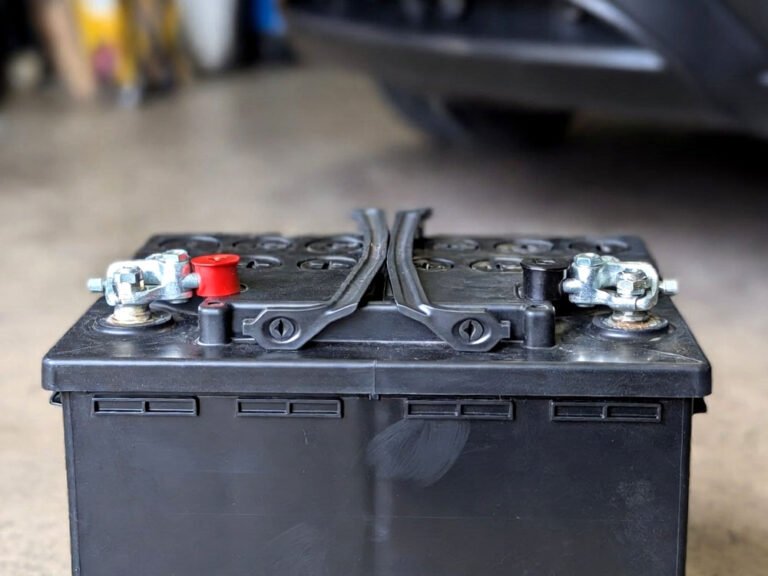

The first time a spark plug just keeps spinning, it feels confusing. You expect resistance, then freedom, then the plug pops out. Instead, it rotates like a loose doorknob. Most of the time, this means the threads in the cylinder head are damaged or partially stripped. Aluminum heads are soft, and over time heat cycles and over tightening can slowly chew those threads away. When the threads fail, the plug no longer climbs upward as it turns.

Another common cause is carbon buildup. I once pulled plugs from an old truck that had been running rich for years. Carbon had built up around the lower threads, acting like glue. The plug spun freely above that carbon ring but refused to lift. It felt like the plug was teasing me. This situation is less dangerous than stripped threads, but it still requires patience and finesse.

Cross threading is another culprit. If a plug was installed slightly crooked, it can damage only part of the threads. When you remove it, the good threads spin while the damaged ones hold it hostage. You feel movement, but no progress. That uneven damage is why tightening slightly can sometimes help realign things.

Understanding the cause matters because the fix depends on it. Panic leads to broken plugs or worse, metal shavings inside the cylinder. Slow thinking saves engines.

- Spinning usually means thread damage or carbon buildup

- Aluminum heads are more vulnerable to this issue

- Carbon can trap plugs even when threads are intact

- Cross threading creates uneven resistance

What It Feels Like When Threads Are Stripped

There is a very specific feeling when threads are stripped. The ratchet feels smooth, almost too smooth, with no gritty resistance. I remember thinking something felt wrong, like tightening a screw into air. When a spark plug won’t come out just keeps spinning, your hands are the first warning sign. Trust them. That smooth spinning means the plug is no longer engaging the threads properly.

Emotionally, this is where frustration creeps in. You start questioning every past repair. Did I over tighten it last time? Did the previous owner use an impact gun? These thoughts matter less than your next move. If you keep spinning, you risk pulling aluminum out with the plug or snapping it off entirely. That is when a simple tune up becomes a head removal job.

Visually, you might notice the plug rising slightly, then dropping back down. That tiny movement can mean only a few threads are left. This is where upward pressure helps. A spark plug socket with a rubber insert can sometimes grip enough to lift the plug as you turn, buying you a little progress with each rotation.

The key here is awareness. The moment spinning feels endless, you stop treating it like a normal removal. You shift into problem solving mode, slow and deliberate.

- Smooth spinning is a major warning sign

- Continued turning increases damage risk

- Slight up and down movement signals partial threads

- Awareness prevents expensive mistakes

Gentle Tricks That Actually Work

One trick I learned the hard way is tightening before loosening. It sounds wrong, but it works. By turning the plug slightly tighter, you can sometimes re engage damaged threads just enough to start backing it out properly. I have saved more than one cylinder head this way, and it always feels like a small miracle when it works.

Penetrating oil is another lifesaver, but only if you use it correctly. Spray it, then walk away. Go get coffee. Let gravity and capillary action do their thing. Rushing this step is a mistake I see all the time. Heat cycling the engine slightly before spraying can also help draw the oil into stubborn carbon deposits.

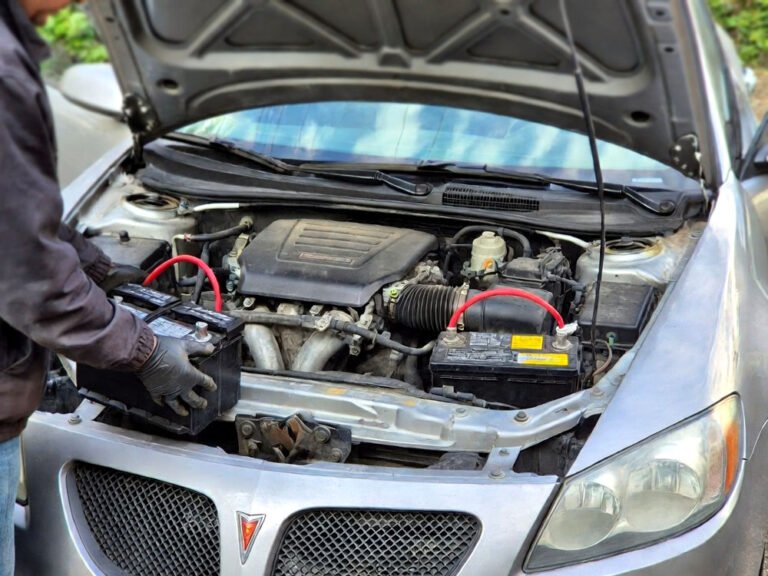

Upward pressure is critical. I once used a magnetic pickup tool resting under the socket to gently pull up while turning. Others use a pry bar carefully placed under the ratchet handle. The goal is gentle lift, not brute force. You are encouraging the threads to climb, not yanking them free.

If the plug still spins, stop and reassess. Every extra rotation without progress increases the chance of failure. Patience here saves thousands later.

- Slight tightening can re engage threads

- Penetrating oil needs time to work

- Gentle upward pressure helps threads climb

- Stopping early prevents major damage

When Carbon Buildup Is the Real Enemy

Carbon buildup is sneaky. The plug threads might be fine, but the carbon ring below them acts like a clamp. I dealt with this on an old lawn mower engine that had never seen fresh fuel. The plug spun happily but refused to move up. The fix was slow back and forth motion combined with penetrating oil and patience.

In these cases, tightening and loosening in small increments helps break the carbon seal. Think of it like rocking a stuck jar lid rather than twisting harder. Each small movement crushes carbon flakes until the plug finally starts to rise. You can sometimes hear faint cracking sounds, which is a good sign here.

Heat can help too. Warming the engine slightly expands the metal around the carbon, loosening its grip. Just be careful. Hot aluminum strips easily. Warm, not hot, is the goal. Gloves help you stay controlled rather than reactive.

Once removed, always inspect the plug threads. Carbon packed tightly on the lower threads tells the story. Cleaning the hole before installing a new plug prevents repeat problems and keeps torque readings accurate.

- Carbon can trap plugs even with good threads

- Small back and forth motions break carbon seals

- Light engine warmth helps release buildup

- Cleaning threads prevents future issues

Knowing When to Stop and Use Repair Tools

There is a moment when you need to stop trying clever tricks. If the spark plug won’t come out just keeps spinning with no upward movement at all, threads are likely gone. Continuing risks pulling aluminum out or dropping debris into the cylinder. That is when thread repair tools come into play.

Helicoil and thread insert kits exist for a reason. I used to fear them, thinking they meant engine death. In reality, they can restore threads stronger than stock if done carefully. The key is keeping metal shavings out of the cylinder, usually with grease on the tap and careful vacuuming.

Sometimes the plug breaks before you reach this stage. Broken plug extractors exist, and they work, but they demand patience. Rushing here almost guarantees more damage. If you feel out of depth, this is the moment to call a professional. Pride is expensive in engine work.

Knowing when to stop is a skill. It separates successful DIY mechanics from horror stories shared online.

- Endless spinning with no lift means stripped threads

- Thread inserts can permanently fix the issue

- Cleanliness is critical during thread repair

- Calling a pro can save money long term

Preventing This Problem Next Time

Prevention is the quiet hero here. Always start spark plugs by hand. I cannot stress this enough. Feeling the threads engage smoothly with your fingers prevents cross threading more than any tool ever will. It adds two minutes and saves hours of regret.

Torque matters too. Over tightening is common, especially when working by feel. A torque wrench removes guesswork and protects aluminum threads. Light anti seize on threads can help, but use it sparingly since it alters torque readings.

Regular plug changes also help. The longer a plug sits, the more carbon and corrosion build up. Changing them on schedule keeps removal easy and predictable. I learned this after fighting plugs that had been untouched for a decade.

Finally, slow down. Most spark plug disasters happen when someone is rushing. Calm hands make good engines.

- Hand start plugs every time

- Use a torque wrench for accuracy

- Light anti seize can help when used correctly

- Regular maintenance prevents stuck plugs

Final Thoughts

A spark plug that just keeps spinning is frustrating, but it is not the end of the world. Slow down, listen to what the engine is telling you, and choose patience over force. Most mistakes happen in a hurry. Careful hands and smart pauses save engines and sanity.

| Action | What It Does | Helpful Tip |

|---|---|---|

| Stop turning | Prevents further thread damage | Endless spinning is your warning |

| Apply penetrating oil | Loosens carbon and corrosion | Let it soak at least 15 minutes |

| Tighten slightly | Re engages damaged threads | Only a small movement is needed |

| Apply upward pressure | Helps threads climb out | Use gentle, steady force |

| Warm engine lightly | Expands metal around threads | Warm, not hot, to avoid stripping |

| Inspect threads after removal | Confirms root cause | Look for aluminum or carbon |

| Use thread repair kit | Restores stripped threads | Keep shavings out of cylinder |

Frequently Asked Questions (FAQs)

Is it safe to keep turning a spark plug that spins?

It is not safe to keep turning a spark plug that spins endlessly. While it feels like progress, each rotation can strip more aluminum from the cylinder head. That damage can turn a simple repair into an expensive one. Instead, stop early and switch to controlled methods like upward pressure and penetrating oil. Your engine will thank you for the restraint.

Can penetrating oil really help in this situation?

Yes, penetrating oil can make a big difference, especially when carbon buildup is involved. The oil creeps into tight spaces and breaks down deposits that trap the plug. The key is patience. Spray it, wait, and avoid rushing. Combined with gentle back and forth motion, it often frees stubborn plugs safely.

Do I need special tools if the threads are stripped?

If the threads are stripped, special tools like thread insert kits are usually required. These kits restore the threads to usable condition and can be stronger than the original aluminum. While intimidating at first, many DIY mechanics succeed by following instructions carefully. Cleanliness and patience are more important than experience.

Is it okay to drive with a spinning spark plug?

Driving with a loose or spinning spark plug is risky. It can lead to compression leaks, misfires, and further thread damage. In worst cases, the plug can eject from the head under pressure. If you notice this issue, stop driving and address it before starting the engine again.

Can carbon buildup alone cause endless spinning?

Yes, heavy carbon buildup can cause a plug to spin without coming out. The threads may be intact, but carbon acts like a clamp. This is more common in engines that run rich or burn oil. Careful back and forth motion combined with oil usually solves this without permanent damage.

Do I need to remove the cylinder head if this happens?

Most of the time, you do not need to remove the cylinder head. Many stuck or spinning spark plugs can be fixed in place with patience and the right tools. Head removal is usually a last resort when plugs break badly or thread damage is severe beyond repair inserts.

Is it my fault if this happens?

Not always. Many spinning spark plugs are the result of previous work, age, or engine conditions. Over tightening, cross threading, or long service intervals can all contribute. Focus less on blame and more on careful repair. Learning from it prevents repeat problems.

Can anti seize prevent this problem next time?

Anti seize can help prevent plugs from sticking, especially in aluminum heads. Use a very small amount and adjust torque accordingly. Too much can cause over tightening. When used correctly, it makes future removal smoother and reduces the risk of seized or spinning plugs.