Your car refuses to start, the key is missing, and you’re stuck in a parking lot. This happens more often than people admit. I once saw a driver tow a perfectly good car because of a bad ignition switch and no key. The good news is, this repair is possible at home. You just need patience, the right approach, and a clear plan.

Disconnect the battery to avoid airbag issues, remove steering column covers carefully, locate the ignition switch behind the lock cylinder, release or bypass the lock cylinder without the key, install the new ignition switch correctly, reconnect wiring firmly, test electrical functions before full reassembly, and verify smooth engine start after installation.

Understanding the Ignition Switch System

The ignition switch is more than a place where your key goes. It is the main electrical gatekeeper for your car. When it turns, it sends power to the starter, fuel system, and dashboard electronics. Without it working correctly, your engine stays silent. Understanding this helps you avoid breaking related parts while working. Many drivers confuse the ignition switch with the lock cylinder, but they are different components connected closely inside the steering column.

Inside the column, the lock cylinder handles the physical key movement, while the ignition switch handles electrical signals. When your key is lost or broken, the lock cylinder cannot rotate normally. However, the ignition switch itself can still be replaced if accessed correctly. This is why knowing where each part sits matters before grabbing tools. Rushing here often leads to broken plastic housings or damaged wiring connectors.

Most modern vehicles use shear bolts or security screws to protect the ignition assembly. These are designed to snap when installed at the factory. Removing them takes patience and proper tools, like a punch or extractor. Once removed, access becomes easier. Older vehicles are simpler, but still require care to avoid steering wheel lock damage.

Learning the system layout first saves hours of frustration. You work cleaner, safer, and avoid unnecessary part replacement. This knowledge also helps you decide if the job is within your comfort level before starting.

- Ignition switch controls electrical power

- Lock cylinder handles physical key movement

- Steering column houses both parts

- Security bolts require careful removal

Tools and Safety Preparation Before You Start

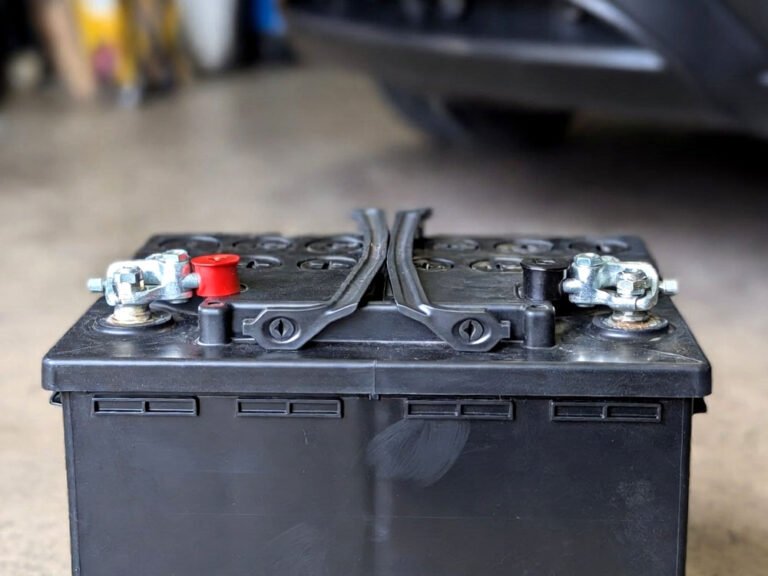

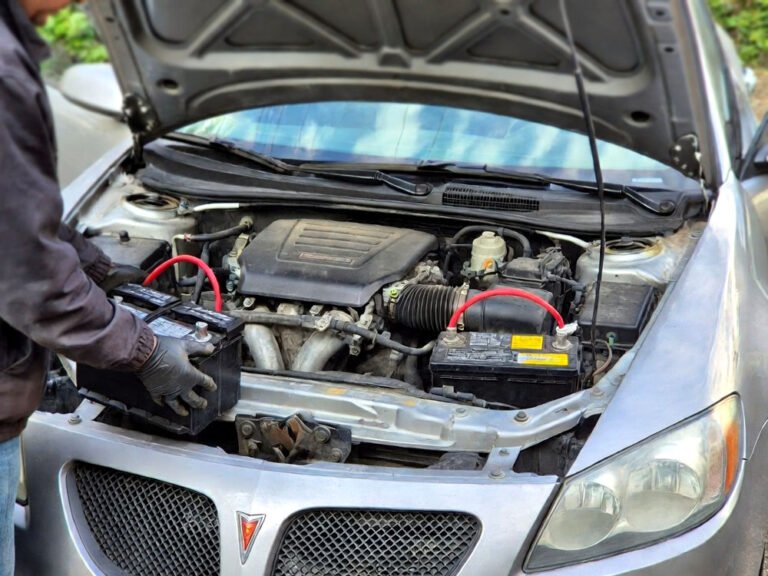

Before touching the steering column, safety comes first. Always disconnect the battery and wait at least fifteen minutes. This prevents accidental airbag deployment, which can cause serious injury. Many cars have airbags mounted directly in the steering wheel, and even small electrical signals can trigger them if you skip this step.

You will need basic hand tools, but the right ones matter. A flathead screwdriver, Phillips screwdriver, socket set, Torx bits, and needle-nose pliers are common. For cars with shear bolts, a hammer and punch or bolt extractor is useful. Keep a magnetic tray nearby to avoid losing tiny screws that hold column covers together.

Lighting is often overlooked. Working under the dashboard is dark and cramped. A headlamp or small LED work light helps you see wiring colors and release tabs without guessing. This reduces broken clips and damaged connectors. Gloves are optional, but thin mechanic gloves protect your hands from sharp metal edges.

Lastly, organize your workspace. Lay parts in the order you remove them. Take photos with your phone before disconnecting wiring. These images become your reference during reassembly. Preparation may feel slow, but it prevents mistakes that could leave your steering wheel stuck or electronics dead.

- Disconnect battery and wait

- Gather correct hand tools

- Use proper lighting

- Organize parts carefully

Removing the Steering Column Covers

Steering column covers hide everything you need to access. They are usually plastic and held by screws underneath the column. Start by adjusting the steering wheel to its lowest and most extended position. This creates more room to work and prevents stress on the plastic tabs during removal.

Carefully remove the screws and place them aside. Some covers snap together, so gentle prying is needed. Use a plastic trim tool or flathead wrapped with tape to avoid scratching surfaces. Never force the covers apart. If they resist, double-check for hidden screws near tilt levers or behind rubber plugs.

Once loose, separate the upper and lower covers slowly. Watch for wiring connected to switches like turn signals or wipers. These usually stay attached, but rough handling can damage connectors. Lower the bottom cover first, then lift the top cover away from the steering column.

With covers removed, you will see the ignition assembly clearly. Take a moment to study how parts align. This visual reference helps later during reassembly. At this stage, do not touch the ignition switch yet. Confirm you can see the lock cylinder, wiring harness, and mounting bolts clearly.

- Adjust steering wheel position

- Remove screws gently

- Pry covers carefully

- Observe assembly layout

Releasing the Ignition Lock Without a Key

Replacing an ignition switch without a key requires bypassing or removing the lock cylinder. Many vehicles have a small release pin underneath the cylinder. Normally, the key must be in the “ON” position to press it. Without a key, drilling becomes the last option.

If drilling is needed, use a small drill bit and go slowly. Drill where the release pin sits, not directly into the switch. This frees the lock cylinder so it can slide out. Wear eye protection and keep metal shavings away from wiring. Precision matters more than speed here.

Some cars allow the ignition switch to be removed without fully extracting the lock cylinder. In these cases, unplug the wiring harness from the switch first. Then remove mounting screws or bolts securing the switch to the column. Slide the switch straight back without twisting to avoid breaking alignment tabs.

Once removed, compare the old switch with the new one. Check connector orientation and mounting points. Differences can indicate incorrect parts. Confirm everything matches before installation. Taking time here prevents reinstalling everything twice.

- Locate lock cylinder release

- Drill carefully if required

- Disconnect wiring harness

- Compare old and new parts

Installing the New Ignition Switch Correctly

Installing the new ignition switch is about alignment and gentle handling. Slide the switch into position exactly as the old one sat. Misalignment can cause starting issues or steering lock problems later. Make sure the switch actuator engages smoothly with the column mechanism.

Secure the switch using original screws or replacement bolts. Tighten firmly but avoid over-tightening, which can crack plastic housings. Reconnect the wiring harness until you hear or feel a solid click. Loose connections cause intermittent power loss that is hard to diagnose later.

Before reinstalling the lock cylinder or column covers, reconnect the battery temporarily. Test electrical functions like dashboard lights, radio power, and starter engagement. If everything works, disconnect the battery again before final reassembly. This extra check saves time if adjustments are needed.

Once confirmed, reinstall the lock cylinder if applicable. Then replace steering column covers in reverse order. Ensure no wires are pinched. Adjust the steering wheel back to normal position. Reconnect the battery fully and perform a final start test.

- Align switch carefully

- Secure without overtightening

- Test electronics early

- Reassemble patiently

Common Mistakes and How to Avoid Them

One common mistake is skipping battery disconnection. This can trigger airbags or blow fuses. Always follow safety steps even if you are confident. Another mistake is forcing parts. Steering column components are fragile and expensive if broken.

Using incorrect drill placement damages the ignition housing. Always confirm release pin location before drilling. Rushing this step often turns a simple repair into a steering column replacement. Slow, controlled drilling is safer and cleaner.

Mixing screws during reassembly causes alignment issues. Screws vary in length and threading. Using the wrong one can crack plastic or fail to secure parts properly. Organize hardware as you remove it to avoid confusion later.

Finally, not testing before full reassembly wastes time. Always test the new ignition switch before reinstalling covers. This allows easy access if adjustments are needed. Learning from these mistakes helps you finish the job smoothly and confidently.

- Disconnect battery always

- Avoid forcing components

- Drill precisely

- Test before full assembly

Final Thoughts

Replacing an ignition switch without a key looks intimidating, but it’s manageable with patience and preparation. Take your time, follow each stage carefully, and respect the steering column components. Done correctly, you save towing fees and repair costs. More importantly, you gain confidence working on your own vehicle, which pays off in future repairs.

Frequently Asked Questions (FAQs)

Is it safe to replace an ignition switch without a key?

Yes, it is safe if you follow proper safety steps. Disconnecting the battery is critical to avoid airbag deployment. Using correct tools and working slowly reduces risks. Many mechanics perform this repair daily without issues.

Can I drive my car after replacing the ignition switch without a key?

You can drive once the new switch is installed and functions properly. However, you may still need a new key or lock cylinder to secure the vehicle. Testing steering lock and starting reliability is important before driving.

Do I need special tools to replace the ignition switch?

Basic hand tools work for most vehicles. Some cars require a drill or extractor for shear bolts. Having proper lighting and trim tools makes the job easier and cleaner.

Is it legal to replace an ignition switch without a key?

Yes, if you own the vehicle. Laws vary, but replacing parts on your own car is generally allowed. Keep proof of ownership handy in case questions arise.

Can I reuse my old lock cylinder?

Sometimes yes, if it is undamaged and you still have a key. Without a key, most people replace it. Matching new keys improves security and reliability.

Do I need to program anything after replacement?

Older cars usually need no programming. Newer vehicles with immobilizers may require key programming. Check your car’s system before starting the job.

Is it cheaper to do this myself?

Absolutely. Doing it yourself saves labor costs. Parts are usually affordable, and the main investment is time and patience.

Can I damage my steering wheel lock?

Yes, if you force components or misalign parts. Gentle handling and correct alignment prevent steering lock damage. Always test movement before driving.