You should know this problem hits at the worst time. Your GM key snaps, gets lost, or the cylinder jams solid and won’t turn. I’ve seen cars stuck in driveways for weeks over this tiny part. The good news is that removing a GM ignition lock cylinder without a key is possible if you understand how it locks into the column. Let’s break it down in a way that actually works.

Disconnect the battery and wait to avoid airbag issues, remove the steering column covers carefully without breaking clips, locate the lock cylinder retaining pin area, drill a precise access hole if the key won’t turn, depress the retaining pin with a punch, slide the old cylinder straight out, clean the housing, and prepare the new cylinder correctly before reinstalling.

Understanding How GM Ignition Lock Cylinders Actually Lock In

Before touching tools, it helps to understand what you’re fighting against. GM ignition lock cylinders are held in place by a spring-loaded retaining pin. Normally, you turn the key to the RUN position, press the pin, and the cylinder slides out. Without a key, that pin stays hidden and locked, which is why people get stuck.

Inside the steering column, the cylinder sits in an aluminum housing. The pin lines up with a small access channel only when the key is turned. When the key is missing or broken, drilling becomes the workaround. This isn’t brute force; it’s controlled access. You are creating a new path to reach that pin without damaging the column.

Different GM models share the same design logic. Chevy, GMC, Buick, and Cadillac columns from the late 90s through mid-2010s are very similar. Tilt columns and non-tilt columns change access angles, not the core idea. Knowing this keeps you from drilling in the wrong place and ruining the housing.

Once you understand that the cylinder itself is disposable but the housing is not, your mindset changes. The goal is clean removal, not destruction.

- The retaining pin is the real lock

- The housing must stay intact

- Drilling is controlled, not aggressive

- Most GM columns use similar layouts

Tools You Actually Need Before Starting

Skipping the right tools is how people crack column covers or damage wiring. You don’t need a full shop, but you do need specific items. A basic socket set removes column trim, while a Torx driver handles GM screws. A drill with sharp bits is essential, not optional.

Use a small center punch before drilling. This prevents the bit from walking and chewing into the aluminum housing. A flashlight or headlamp helps you see the pin once the hole is drilled. Keep a flat punch or sturdy pick ready to press the retaining pin inward.

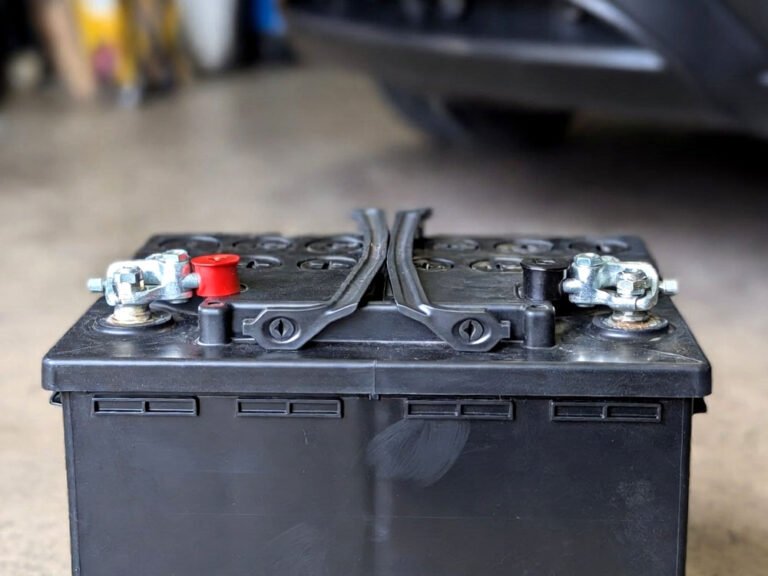

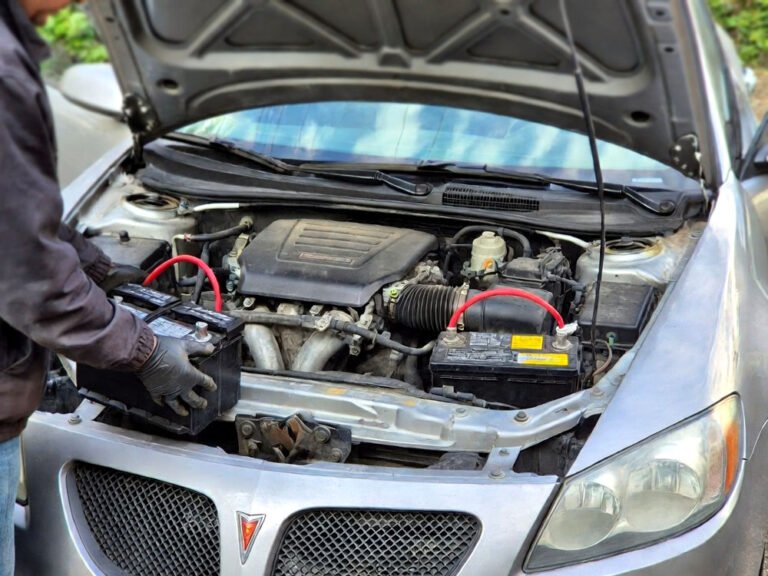

Safety matters more than speed. Disconnect the battery and wait at least 10 minutes so the airbag system fully powers down. GM airbag modules sit close to the column, and accidental deployment can cause serious injury.

Having everything laid out before starting saves frustration. Once the column is open, stopping midway invites mistakes. Preparation is what separates a clean removal from a steering column replacement.

- Torx drivers and sockets are mandatory

- Drill bits must be sharp and small

- Battery disconnection is non-negotiable

- Light and visibility reduce errors

Removing the Steering Column Covers Safely

The column covers are fragile, especially on older GM vehicles. Start by lowering the steering wheel to its lowest position. This gives you room and reduces stress on the plastic. Remove the screws from the underside first; most are Torx T15 or T20.

Separate the upper and lower covers slowly. Hidden clips snap easily if forced. Wiggle gently while pulling apart instead of prying hard. If it feels stuck, double-check for missed screws. GM loves hiding one behind the tilt lever area.

Once the covers are off, you’ll see the ignition cylinder housing clearly. Take a moment to clean dirt and debris. This keeps junk from falling inside when drilling. Also locate wiring for the Passlock sensor and ignition switch so you don’t drill into them accidentally.

This stage sets the tone for the whole job. Calm, slow movements prevent cosmetic damage and keep the column solid for reassembly.

- Lower the wheel before starting

- Never pry aggressively on plastic

- Clean the area before drilling

- Identify wiring paths early

Drilling the Access Hole the Right Way

Drilling scares people, but precision makes it safe. Look at the bottom or side of the ignition cylinder housing where the retaining pin sits. Many GM columns even have a faint casting mark showing where to drill. Use a center punch to mark the spot.

Start with a small drill bit, usually around 1/8 inch. Drill slowly and stop often. You’re only drilling through thin aluminum, not steel. Once through, shine a light inside to locate the retaining pin. Do not enlarge the hole unless absolutely necessary.

Insert a punch or pick and press inward. You’ll feel the spring-loaded pin move. While holding it in, pull the ignition cylinder outward. It should slide free smoothly. If it doesn’t, stop and recheck alignment instead of forcing it.

This method avoids cracking the housing and keeps the new cylinder fitting tight later.

- Drill slowly and carefully

- Use the smallest effective bit

- Stop once aluminum is pierced

- Never force the cylinder out

Removing the Cylinder and Inspecting the Housing

With the pin depressed, the old ignition lock cylinder should come out straight. If it binds, wiggle gently while maintaining pressure on the pin. Twisting hard can damage the housing bore, which causes future ignition problems.

Once removed, inspect the housing closely. Look for burrs from drilling or metal shavings inside. Clean everything with compressed air or a lint-free cloth. Any debris left behind can cause the new cylinder to stick or fail early.

Check the ignition switch actuator rod behind the cylinder. It should move freely. If it feels loose or jammed, fix that before installing the new part. Many people blame new cylinders when the real issue is a damaged actuator.

This inspection step saves repeat labor and ensures smooth key operation later.

- Pull the cylinder straight out

- Clean metal shavings thoroughly

- Inspect the actuator rod

- Fix housing damage immediately

Installing the New Cylinder and Testing

Before installing the new ignition lock cylinder, turn it to the RUN position using its new key. This aligns the retaining pin properly. Slide it into the housing until it clicks. That click confirms the pin engaged fully.

Reconnect the battery temporarily and test key movement. Ensure the wheel unlocks, accessories power on, and the engine cranks. If everything feels smooth, reinstall the column covers carefully in reverse order.

If your GM vehicle uses Passlock, a relearn procedure may be needed. This usually involves cycling the key and waiting through timed intervals. Follow your model-specific process to avoid a no-start condition.

Final testing ensures you won’t be pulling the column apart again.

- Align the new cylinder correctly

- Listen for the retaining click

- Test before reassembly

- Perform Passlock relearn if needed

Final Thoughts

Removing a GM ignition lock cylinder without a key looks intimidating, but it’s manageable with patience and precision. Take your time, protect the column, and focus on the retaining pin—not brute force. Done right, this fix restores full function without expensive towing or dealer labor.

| Action | Details | Pro Tip |

|---|---|---|

| Disconnect battery | Prevents airbag deployment | Wait 10 minutes minimum |

| Remove column covers | Access ignition housing | Check for hidden screws |

| Mark drill point | Align with retaining pin | Use a center punch |

| Drill access hole | Small, controlled drilling | Stop as soon as aluminum breaks |

| Depress retaining pin | Releases cylinder | Use a flat punch |

| Remove cylinder | Slide straight out | Don’t twist aggressively |

| Clean housing | Remove metal shavings | Compressed air works best |

Frequently Asked Questions (FAQs)

Is it safe to remove a GM ignition lock cylinder without a key?

Yes, it is safe if you disconnect the battery and follow the correct drilling method. The biggest risk comes from rushing and damaging the housing or triggering the airbag. Take time, use proper tools, and drill only where necessary.

Can this method damage my steering column?

It can if done carelessly. Drilling too deep or in the wrong spot can crack the housing. Staying precise and using small drill bits keeps the column intact and reusable.

Is it legal to remove an ignition lock cylinder without a key?

Yes, if you own the vehicle or have permission. This is a repair procedure, not a theft technique. Always ensure you’re working on your own car.

Can I do this without drilling?

Usually no. Without a working key, the retaining pin cannot be accessed normally. Drilling is the standard professional workaround used by locksmiths and mechanics.

Do I need a locksmith to do this job?

Not necessarily. With patience and basic tools, many DIYers succeed. However, if you’re uncomfortable drilling near the column, a locksmith may be safer.

Is it necessary to replace the ignition switch too?

No, the ignition switch is separate from the lock cylinder. Replace it only if you notice electrical issues or binding after cylinder removal.

Can a bad ignition cylinder cause a no-start?

Yes. Worn tumblers or a stuck pin can prevent proper key rotation and trigger security systems, leading to no-crank or no-start issues.

Do I need to reprogram anything after replacement?

Some GM vehicles require a Passlock relearn. This doesn’t need special tools, just time and following the correct key cycle procedure.