You know that moment when your brakes start squeaking on the way to work and you think, “Not today, I’m not paying a mechanic”? I’ve been there, hands greasy, under the car, staring at the caliper like it’s a puzzle from another dimension. Changing brake pads without removing the caliper sounds impossible, but it’s actually doable with a little patience and the right technique. Imagine slipping new pads in, hearing that satisfying click, and knowing your car stops like new, all without dismantling half the brake system. Let’s dive into how to make it happen smoothly.

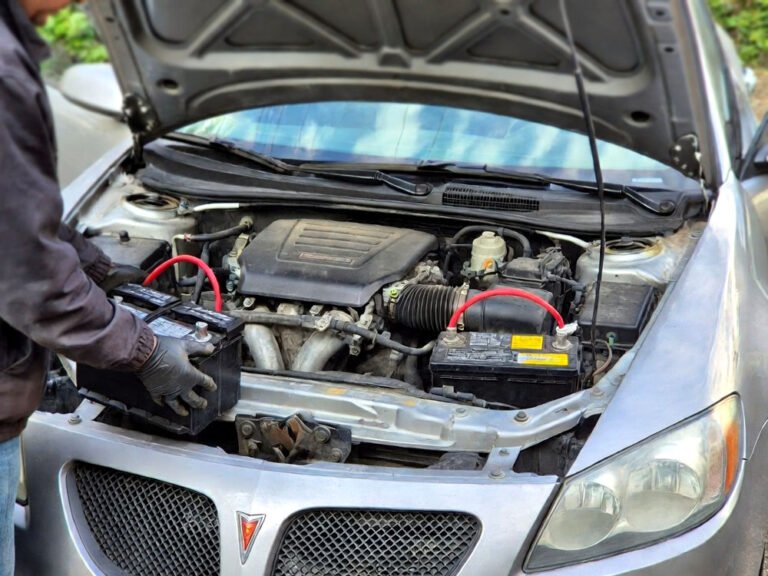

Loosen the wheel lug nuts, lift the car securely, and remove the wheel. Use a C-clamp or brake piston tool to gently compress the caliper pistons. Slide out the old brake pads carefully while keeping the caliper in place. Inspect the rotor for scoring or damage and clean the bracket with a wire brush. Install the new pads with proper alignment, add brake grease to prevent squeaks, and slowly retract the caliper onto the new pads. Finally, tighten bolts and wheel nuts, lower the car, and test brakes carefully.

Prepare Your Workspace and Tools

Before touching the brakes, setting up a comfortable workspace is key. I remember the first time I tried to swap brake pads without removing the caliper—it ended with grease on my hoodie and a dropped wrench. Have a flat surface, jack stands, and wheel chocks ready. Your tools should include a C-clamp, socket set, gloves, brake grease, and clean rags. Safety goggles help keep grime or dust out of your eyes. Trust me, nothing ruins a DIY session like an unexpected eyeball full of brake dust.

Once the wheel is off, take a moment to inspect everything. Look for rust, leaks, or warped rotors. This is your opportunity to catch small issues before they turn into expensive problems. Lay the tools in reach and keep a small tray for bolts to avoid losing them. A tidy workspace makes the process feel easier and less stressful, like laying out ingredients before cooking a fancy meal.

With your environment prepped, you’ll notice a mental shift: this doesn’t feel like a chore anymore. You can approach each part with patience rather than panic. Having everything ready is the secret to swapping pads without removing the caliper.

- Ensure flat, safe workspace

- Gather all tools before starting

- Inspect brakes and rotors visually

- Use trays for bolts and small parts

Compress the Caliper Piston Safely

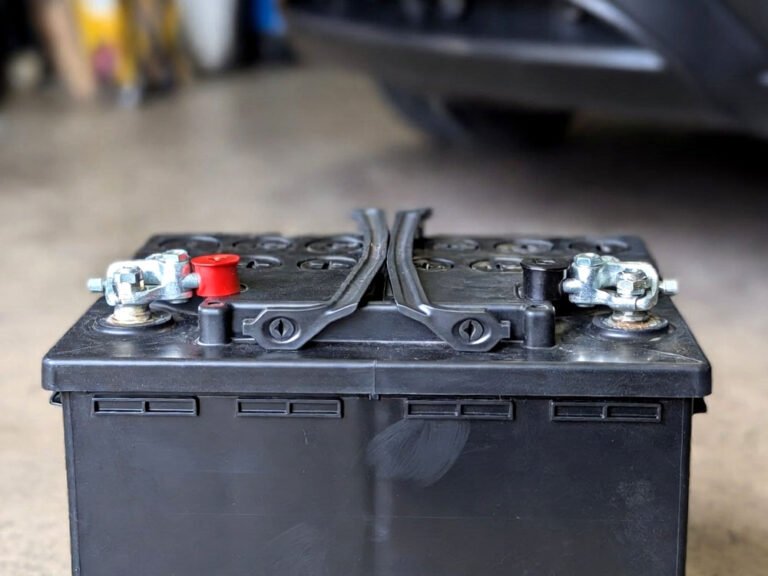

One of the trickiest parts is pushing the caliper piston back without damaging it. I’ve had a piston spring out once, and cleaning brake fluid off the garage floor was a nightmare. Use a C-clamp or a dedicated brake piston tool. Place a rag behind the piston to avoid scratches and slowly turn the clamp screw. The piston should move evenly; if it’s stiff, never force it—apply a little brake cleaner or check for debris.

This step is where patience pays off. Compressing too fast can bend the caliper bracket or damage the rubber seal, which leads to leaks later. Compress in small increments and watch the piston gradually retreat. You’ll feel the resistance lessen as it settles back into the caliper. Imagine slowly closing a stubborn drawer rather than slamming it shut.

If your car has dual pistons, repeat the process evenly. Uneven compression can cause the pads to sit crooked, leading to uneven braking. Once compressed, wipe off any excess brake fluid to prevent corrosion. This simple preparation ensures your new pads fit perfectly without removing the caliper.

- Use C-clamp or piston tool

- Compress slowly to avoid damage

- Protect caliper seals with a rag

- Repeat evenly on dual pistons

Remove Old Brake Pads

Sliding out the old pads without touching the caliper can feel like a magic trick at first. Use a flat screwdriver or pry bar gently to pop them free. I usually brace my hand against the bracket to prevent slipping—nothing worse than losing a pad into the wheel well. Watch out for clips or retaining pins that hold the pad in place. Removing them carefully saves headaches when installing new pads.

Check each pad for uneven wear. I once ignored one pad with a small crack, installed new ones, and heard a rattle for weeks. Old pads can also leave residue on the caliper bracket, so a quick clean with a wire brush or brake cleaner helps everything slide smoothly. Clean surfaces reduce noise and improve brake performance.

Keep track of shims and anti-rattle clips—they usually come off with the pad. I recommend storing them in a labeled bag; it sounds trivial, but it saves you from redoing the whole process. Once the old pads are out, inspect the rotor surface for deep grooves. Light scoring is normal, but heavy damage may require resurfacing.

- Use flat tool to gently pry pads

- Inspect for cracks or uneven wear

- Clean bracket and rotor surface

- Keep shims and clips organized

Install New Brake Pads

Now comes the satisfying part: inserting the new pads. Apply a thin layer of brake grease on the contact points where the pad touches the caliper bracket. This prevents squeaks and keeps movement smooth. Slide the pads into place carefully, ensuring they align perfectly with the rotor. A little wiggle is normal, but they should fit snugly.

I like to press down on the bracket gently while sliding the pad in. It gives that reassuring click and ensures the pad doesn’t bind against the caliper piston. Never force it; if it doesn’t fit, the piston may need more compression. Small adjustments make a huge difference in brake performance and longevity.

Finally, check that any clips or anti-rattle hardware are correctly seated. Misaligned hardware can cause vibration and noise. Once everything feels secure, slowly retract the caliper over the new pads and tighten the bolts evenly. Stand back and admire the almost meditative simplicity of the process.

- Apply brake grease to contact points

- Align pads carefully with rotor

- Ensure clips and shims are in place

- Retract caliper slowly and tighten bolts

Check Brake Fluid and Pedal Feel

Even without removing the caliper, your brake fluid may need attention after compressing the pistons. I always check the master cylinder reservoir before finishing. If fluid is near the top, remove a little to avoid overflow. Too much fluid can make bleeding unnecessary but prevent mess.

Next, press the brake pedal slowly several times. You should feel firm resistance after a few pumps as the pads seat against the rotor. A spongy pedal may indicate trapped air or improper installation. Take a moment to listen for any unusual sounds during the first few presses. Subtle squeaks are normal, but scraping or grinding requires inspection.

A common tip I follow: test the car in a safe, empty parking lot. Gradually increase braking force while listening, feeling, and smelling the system. This step builds confidence and ensures safety before hitting the road for real. Proper fluid check and pedal feel assessment prevent surprises later.

- Check master cylinder level

- Slowly press brake pedal

- Listen for unusual sounds

- Test brakes in safe area

Final Brake Inspection and Road Test

After installation, a thorough inspection is crucial. Look for loose bolts, misaligned pads, and any brake fluid leaks. I always give the caliper a gentle shake to confirm it’s seated correctly. Even small vibrations can signal a problem. Take your time; rushing this step could undo all your hard work.

When ready, start with short, low-speed stops in a clear area. Gradually increase speed while observing brake response. Pay attention to noise, pedal firmness, and any unusual pull to one side. If anything feels off, stop immediately and double-check installation. Proper road testing ensures your DIY brake job is both safe and effective.

Remember, brake maintenance isn’t just about the parts—it’s about confidence. Knowing you replaced pads correctly without removing the caliper builds skill and independence. It’s a mix of patience, care, and a bit of fun under the hood.

- Inspect bolts and pads

- Check for leaks or vibration

- Perform slow, cautious test stops

- Observe brake response and pedal feel

Quick Guide Table

| Action | Details | Tips & Notes |

|---|---|---|

| Lift Car | Use jack and stands | Ensure stable surface, use wheel chocks |

| Remove Wheel | Loosen lug nuts | Keep a tray for nuts and bolts |

| Compress Piston | Use C-clamp or brake tool | Place rag behind piston to prevent scratches |

| Remove Old Pads | Pry gently with screwdriver | Inspect for cracks, store clips safely |

| Clean Bracket | Wire brush or brake cleaner | Remove rust and residue |

| Install New Pads | Apply brake grease | Ensure proper alignment, seat clips |

| Retract Caliper | Slowly over new pads | Tighten bolts evenly |

| Test Brakes | Pump pedal, road test | Listen for unusual sounds, check pedal firmness |

Frequently Asked Questions (FAQs)

Is it safe to change brake pads without removing the caliper?

Yes, it’s safe as long as you compress the pistons carefully and ensure the pads slide in properly. Avoid forcing components and always double-check alignment. Use jack stands and a flat surface to prevent accidents. Compress pistons slowly to protect rubber seals, and test brakes in a controlled area afterward. Many DIY enthusiasts swap pads this way without removing the caliper, saving time and keeping the process clean.

Can I reuse old brake pads if they are slightly worn?

It’s not recommended. Even small wear differences can reduce braking efficiency and cause uneven rotor wear. Reusing pads can lead to squeaking, vibration, and heat issues. If pads are below the manufacturer’s minimum thickness, replace them. Minor visual wear might seem okay, but braking performance is more important than saving a few bucks.

Do I need special tools to compress the caliper piston?

A basic C-clamp or a dedicated brake piston tool works for most cars. The tool helps push the piston back evenly without damaging seals. Dual pistons require careful attention to avoid uneven compression. You don’t need expensive tools, but using the right method prevents leaks, uneven pad seating, and costly mistakes.

Is it necessary to clean the caliper bracket?

Absolutely. Rust, debris, and old grease can prevent the pads from sliding smoothly, causing noise and uneven wear. Use a wire brush and brake cleaner to remove buildup. Clean surfaces reduce friction, ensure even pad wear, and improve braking efficiency. This small step makes a surprisingly big difference in brake performance.

Can I change pads on all vehicles without removing the caliper?

Not all vehicles allow this. Some caliper designs require removal to access the pads fully. Check your car’s service manual or inspect the caliper. If the pistons can compress fully and the pads slide out, you can usually avoid removal. Cars with larger calipers or unusual designs may require more disassembly.

Do I need to bleed brakes after compressing the piston?

Usually, no bleeding is needed unless air enters the system or fluid is overfilled. Pump the pedal slowly after installing pads to seat them properly. If the pedal feels spongy, bleeding might be necessary. Checking fluid level before and after installation helps avoid air-related issues.

Is brake grease necessary for new pads?

Yes, applying brake grease to pad contact points reduces noise and ensures smooth movement. Avoid getting grease on the rotor or pad friction surface. A small dab on backing plates and caliper edges is enough. Proper lubrication improves pad longevity and prevents annoying squeaks.

Can worn rotors affect a no-caliper-removal pad change?

Yes, heavily scored or warped rotors can make sliding pads in difficult and cause uneven braking. Lightly scored rotors are fine, but deep grooves may require resurfacing or replacement. Inspect rotor surfaces carefully before starting the pad change to avoid issues later.

Final Thoughts

Changing brake pads without removing the caliper is entirely possible with patience and attention to detail. Take your time with piston compression, alignment, and cleaning. A careful approach prevents damage, ensures smooth braking, and saves a trip to the mechanic. With practice, this process becomes a satisfying, confidence-building DIY skill.