Changing a fuel pump seems like the perfect fix when your car won’t start or feels weak. But many drivers face new issues right after the job. This guide explains the seven most common problems after changing fuel pump, why they happen, and how to solve them fast with simple steps anyone can follow.

Key Takeaways: Check that the new pump is the exact match for your car model and year. Always replace the fuel filter and strainer at the same time. Prime the new pump correctly before starting the engine. Inspect all electrical connectors and wires for damage or loose fit. Reset the fuel system by pulling the fuel pump fuse for ten minutes. Use only fresh, clean gasoline after installation. Listen for unusual pump noise in the first fifty miles. Scan for trouble codes even if the check engine light is off.

Wrong Fuel Pump Installed

Choosing the wrong fuel pump is the number one reason people face problems after replacement. Many parts look the same but have different pressure ratings or connector shapes. A pump made for a V6 engine will not work correctly in a four-cylinder car. Always double-check the part number with your vehicle’s VIN before buying.

Aftermarket pumps sometimes save money but fail faster than original equipment. Cheap pumps often deliver wrong fuel pressure, making the engine run too rich or too lean. This causes hard starting, rough idle, and poor power. Some drivers notice black smoke from the exhaust within days.

Installation mistakes also happen when the pump assembly does not match the tank shape. The float arm can bend or the level sender gives wrong readings. Your fuel gauge may show empty even when the tank is full. In worst cases, the pump sits at wrong angle and burns out quickly.

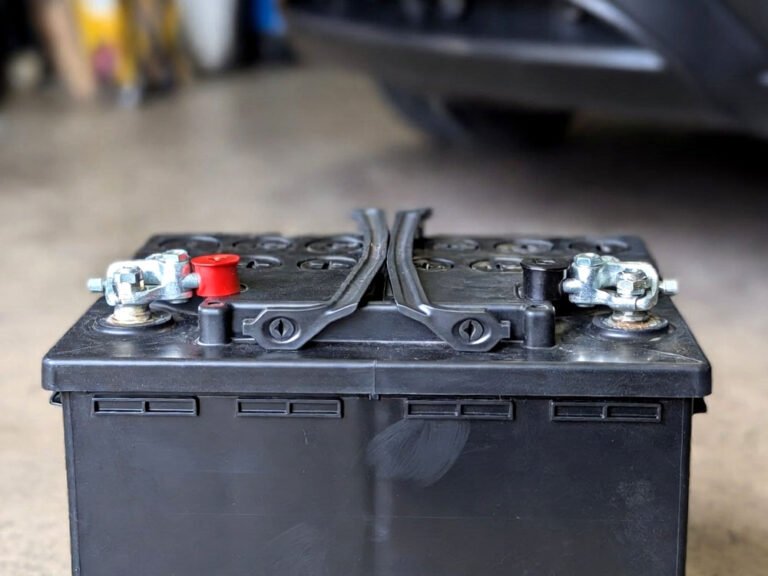

Always compare the old pump and new pump side by side before dropping the tank. Look at connector pins, hose sizes, and mounting clips. Take clear pictures during removal so you install everything exactly the same way. Spending extra time here prevents weeks of trouble later.

- Match exact part number and VIN

- Compare old and new pump visually

- Avoid super-cheap no-name brands

- Check pressure rating in psi

- Test fuel gauge after filling tank

Fuel System Not Primed Correctly

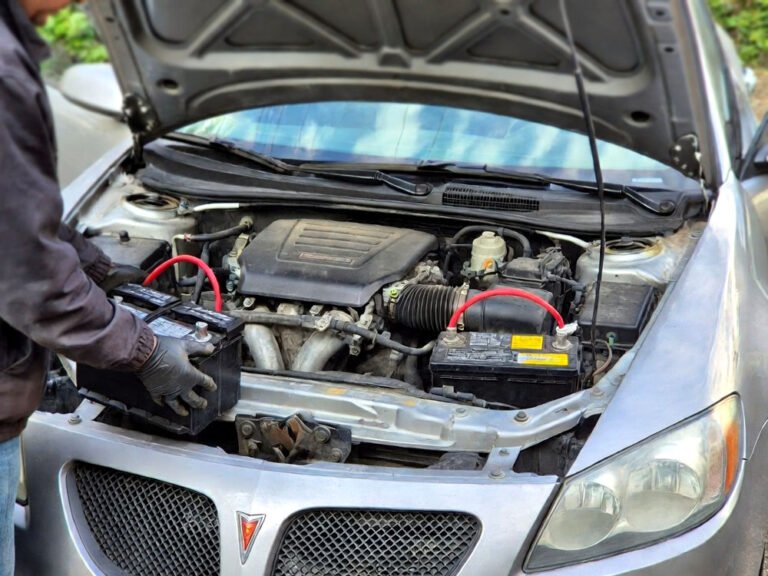

A new fuel pump needs fuel inside before it can work properly. Dry pumps overheat and die within minutes. Many people just install the pump and try to start the car right away. This common mistake kills brand-new pumps every day.

The correct way is to prime the system first. Turn the key to ON position (not start) three or four times for five seconds each. You will hear the pump run and build pressure. This fills the lines and pump with gasoline so it stays cool and lubricated.

Some modern cars have no pressure valve on the fuel rail anymore. In those cars, pour one cup of clean gasoline directly into the pump basket before installing. This small step saves the pump from instant damage. Mechanics who skip priming replace the same pump twice in one week.

After priming, the car should start within three seconds. If it cranks longer, you still have air in the lines. Keep cycling the key until pressure builds. A fuel pressure gauge makes this job much easier and costs less than twenty dollars.

- Cycle key ON five times before starting

- Pour gasoline in basket on newer cars

- Listen for pump sound each cycle

- Use pressure gauge to confirm 40-60 psi

- Never crank engine more than ten seconds at once

Old or Clogged Fuel Filter

Most drivers only change the pump and forget the fuel filter. The old filter often gets completely blocked during the job. Debris from the tank breaks loose and clogs the filter in minutes. The new pump works extra hard and fails fast.

A clogged filter acts like a closed valve. The pump runs constantly trying to push fuel through. This overheats the motor and shortens life from years to weeks. You will notice the car hesitates when you press the gas pedal hard.

Always install a new fuel filter when doing pump work. The filter costs ten to thirty dollars but saves hundreds in repeat repairs. Some cars have the filter built into the pump assembly. In those cases, the whole unit comes with a new filter already.

Check your owner’s manual for filter location. Some sit under the car near the tank, others inside the tank with the pump. Replace external filters every thirty thousand miles even if you did not change the pump. Clean fuel keeps everything running longer.

- Replace filter every pump job

- Check location in manual first

- Use only OEM or top brand filters

- Blow through old filter to see clogging

- External filters easier than in-tank ones

Bad Electrical Connections or Wiring

Fuel pump needs strong twelve-volt power to work right. Loose connectors or corroded wires cause voltage drop. The pump runs slow and cannot build correct pressure. Engine starts hard and loses power under load.

Many tanks have rusty grounds after years of road salt. Clean the ground bolt with wire brush until shiny metal shows. Add dielectric grease to prevent future rust. A bad ground acts exactly like a failing pump.

Look for melted wires or green corrosion on pins. Clean female connectors with electrical contact cleaner. Sometimes the wiring harness gets stretched during tank removal. Check for pulled or broken wires near the tank top.

Use a test light or multimeter to check voltage at the pump connector. You need at least eleven volts when key is ON. Anything lower means wiring problems that will kill the new pump fast. Fix electricity first, then worry about fuel pressure.

- Clean ground connections shiny

- Check voltage at pump connector

- Look for melted or green wires

- Use dielectric grease on pins

- Repair stretched harness with solder

Air Leaks in Fuel Lines

Cracked or loose fuel lines let air enter the system. The pump sucks air instead of gasoline and loses prime. Engine may run fine at idle but die when driving. This problem shows up days after pump replacement.

Old rubber hoses harden with age. They crack when moved during tank dropping. Quick-connect fittings sometimes do not click fully after service. A tiny air leak acts like a major problem.

Spray carb cleaner around lines while engine runs. If RPM changes, you found the leak. Replace damaged hoses with new fuel-rated hose and proper clamps. Never use regular hose clamps on injection lines.

Some cars use nylon lines that break easily. Handle them gently when lowering the tank. A single cracked nylon line means towing and big repair bills. Tape lines together to prevent rubbing damage.

- Check quick-connect fittings click sound

- Replace cracked rubber hoses

- Spray test with carb cleaner

- Use fuel injection hose and clamps

- Protect nylon lines from rubbing

Faulty Fuel Pressure Regulator

The pressure regulator keeps fuel pressure steady at all engine speeds. A stuck or failed regulator sends wrong pressure to injectors. Too high pressure floods the engine, too low pressure starves it.

Many regulators sit on the fuel rail and have vacuum hose. A cracked vacuum hose acts like bad regulator. Engine runs rich and smells strong gasoline. Black smoke and fouled plugs appear fast.

Some cars have returnless systems with regulator inside the tank. Those only come with the complete pump module. If pressure stays high after turning key off, the regulator failed.

Test with fuel pressure gauge connected to rail. Pressure should hold for thirty minutes after shutdown. Quick drop means leaking regulator or injector. Replace the part causing the leak.

- Test pressure with gauge on rail

- Check vacuum hose for cracks

- Pressure should hold after shutdown

- Returnless systems need full module

- High pressure floods, low pressure starves

Final Thoughts

Changing a fuel pump can fix starting problems, but wrong steps create new headaches. Match the exact pump, prime correctly, replace the filter, and check all connections. Most issues after replacement come from small mistakes that are easy to avoid. Follow these steps and your new pump will last one hundred thousand miles or more.

| Problem | Main Cause | Quick Test | Fast Fix |

|---|---|---|---|

| Hard starting | No priming | Key ON hear pump? | Cycle key 5 times |

| Low power | Wrong pump or clogged filter | Fuel pressure gauge reading | New filter + correct pump |

| Gauge reads wrong | Bent float arm | Compare old vs new assembly | Careful installation |

| Pump noisy or fails fast | Bad wiring or ground | Voltage at pump connector | Clean grounds, fix wires |

| Dies while driving | Air leak | Spray test on lines | Replace cracked hoses |

| Rich running, black smoke | Bad pressure regulator | Pressure after key off | New regulator or vacuum hose |

| Check engine light | New trouble codes | Scan tool reading | Fix root cause, not just code |

| Fuel smell | Leaking line or injector | Visual check + pressure hold | Replace damaged part |

Frequently Asked Questions (FAQs)

Is it normal for the new fuel pump to be loud at first?

Yes, some noise the first few days is normal while air leaves the system. A healthy pump makes steady hum you only hear with key ON and engine off. Loud whining that gets worse means wrong pressure or dry running. Check priming steps again and test voltage. Noise that never goes away often means cheap pump or installation mistake. Good pumps become almost silent after one week.

Can I drive right after changing the fuel pump?

Wait at least ten minutes after installation before driving. Cycle the key several times to prime and build pressure. Start the engine and let it idle five minutes in the driveway. Watch for leaks and listen for strange sounds. Check fuel pressure if you have a gauge. Only drive when everything acts normal at idle. Short test drive around the block first is smart.

Do I need to replace the fuel filter every time?

Yes, always replace the filter when doing pump work. Old filters clog fast with debris stirred up from the tank. A ten-dollar filter prevents hundred-dollar pump damage. Some cars have lifetime in-tank screens only, but most need regular filter service. Check your manual for location and interval. Clean fuel is the secret to long pump life.

Is it safe to use aftermarket fuel pumps?

Good aftermarket brands like Delphi, Bosch, or Carter work fine when matched exactly. Avoid no-name cheap pumps from unknown sellers. They fail in weeks and cause exactly the same starting problems again. OEM pumps cost more but last longer and fit perfectly. Spending fifty extra dollars now saves towing and labor later.

Can a bad relay cause pump problems after replacement?

Yes, the fuel pump relay can fail at the worst time. A weak relay gives low voltage and slow pump speed. Swap with another relay of same type to test. Many cars use the same relay for horns or fans. Clicking sound when key turns ON means relay works. No click means bad relay or wiring issue.

Do I need to reset the computer after new pump?

Most cars do not need computer reset, but pulling the fuel pump fuse for ten minutes helps. This clears adaptive memory and lets the system relearn with new parts. Some vehicles need scan tool to reset fuel trim values. Check engine light may come on for a day or two while learning. Drive normally fifty miles for full relearn.

Is it normal to smell gasoline after pump change?

Strong gasoline smell means a leak somewhere. Check all connections and hoses for wet spots. A single drop at the tank seal can smell for days. Tighten loose clamps and replace cracked O-rings. Small leaks turn into big fires fast. Fix any fuel smell the same day it starts.

Can wrong fuel pressure damage new injectors?

Yes, too high pressure washes cylinder walls and destroys rings fast. Too low pressure causes lean running and burned valves. Always test pressure with gauge after installation. Correct pressure keeps injectors clean and engine healthy. Wrong pressure shortens engine life more than any other problem.