Last summer, my buddy’s 2005 Chrysler 300 started acting up on a road trip. The temp gauge climbed way too high, and we pulled over just in time before things got ugly. Turned out the thermostat was stuck closed, trapping heat like a bad prank. We limped to a shop, but the bill stung. Ever since, I’ve tackled these myself. Swapping the thermostat on a 2005 Chrysler 300 isn’t rocket science, and it’ll keep your ride running cool without overheating drama.

Key Takeaways:

Park on a level spot and let the engine cool completely before starting. Gather tools like sockets, pliers, a drain pan, new thermostat rated at 203 degrees, fresh gasket or O-ring, and coolant. Drain coolant by opening the petcock on the radiator until below the thermostat level. Follow the lower radiator hose to locate the housing on the lower front engine side. Remove obstructing parts like the heater tube carefully. Clean all surfaces thoroughly before installing the new one with the bleed valve at the top. Refill coolant slowly and burp the system to avoid air pockets.

Gather Your Tools and Parts

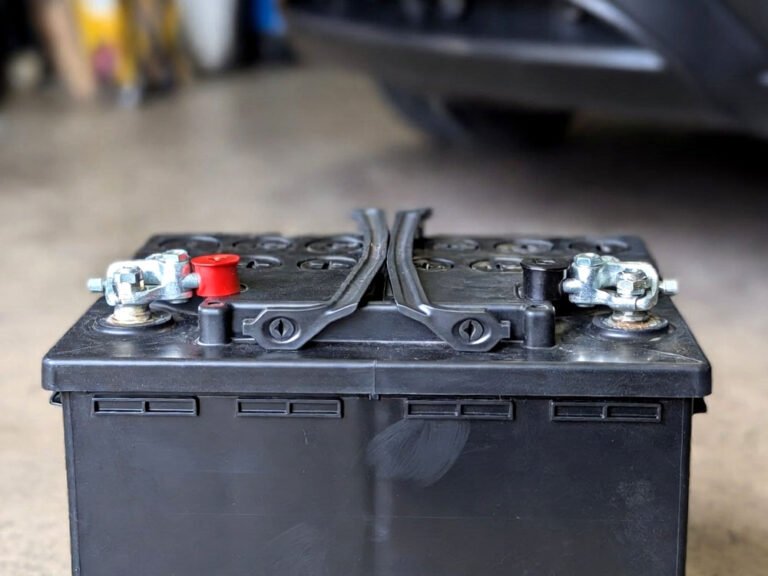

First off, you need the right stuff to make this job smooth. Grab a basic socket set with 10mm and 13mm sockets, extensions, a ratchet, and pliers for hoses. A drain pan catches the coolant mess, and rags help wipe spills. Don’t forget gloves because coolant is slippery and toxic. For parts, pick up a new thermostat, usually around 203 degrees for these engines, plus a fresh O-ring or gasket. Some kits come with the housing if yours looks cracked.

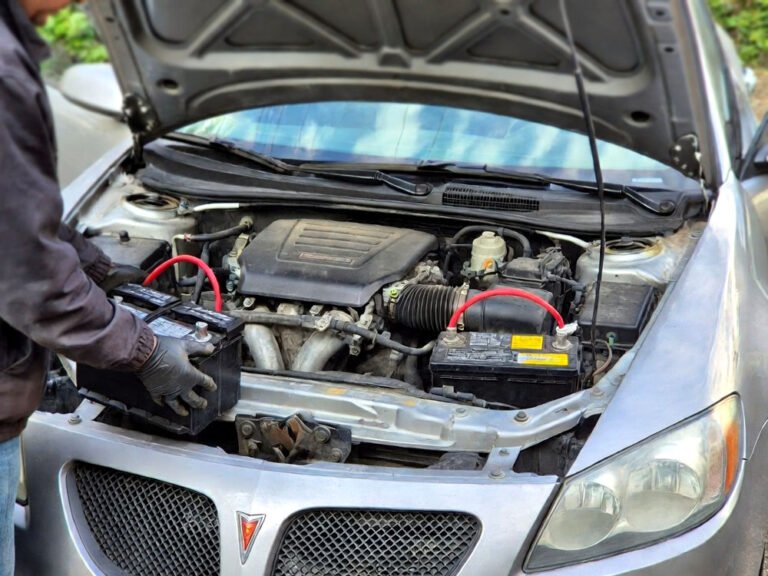

Next, think about access. On the 2005 Chrysler 300, especially with the 2.7L or 3.5L V6, the thermostat sits low on the engine’s front left side. You might need to jack the car up safely or remove the wheel and liner for better reach. A flashlight shines light into tight spots. Having everything ready saves trips back to the store mid-job.

Finally, mix new coolant if you’re topping off. Use the orange stuff specified for Chrysler, 50/50 with water. Old coolant can be recycled at auto parts stores. With tools laid out, you’re set to dive in without frustration.

- Socket set and pliers ready

- New thermostat and gasket on hand

- Drain pan and rags for cleanup

Cool the Engine and Drain Coolant

Start by making sure the engine is stone cold. Hot coolant sprays like a geyser and burns bad. Park overnight if needed. Pop the hood and remove the radiator cap slowly to release pressure. Place your drain pan under the radiator petcock, that little valve at the bottom. Twist it open and let coolant flow out until the level drops below the thermostat housing.

As it drains, watch for chunks or rust, signs of bigger issues. Keep draining until no more comes out easily. Close the petcock tight. Some folks disconnect the lower radiator hose instead for faster drain, but catch the spill. Reuse good coolant if it’s clean by filtering it.

Once drained, you’re safe to work without a flood. This step prevents messes and lets you see clearly. Take your time here, it’s the foundation for the rest.

- Engine fully cooled

- Coolant drained below housing

- Petcock closed securely

Locate and Access the Thermostat Housing

Follow the lower radiator hose from the radiator to the engine. It leads straight to the thermostat housing on the lower front, driver side. On V6 models, it’s tucked low near the water pump. Shine a light and feel around if hidden. You might see two or three bolts holding it.

To get better access, remove anything in the way. Loosen nuts on the heater tube flanges and pull the tube aside gently. Loosen the starter bolt if it brackets the tube. For tight spots, jack the front and remove the driver wheel plus inner fender liner. This opens up room like magic.

With clear view, wipe dirt off. Note how hoses connect for reassembly. Accessing this spot is the trickiest part, but patience pays off.

- Lower hose traced to housing

- Obstructions moved aside

- Good visibility achieved

Remove the Old Thermostat

Now, loosen the bolts on the housing evenly. Use your 10mm socket and extension. They might be stubborn from heat cycles, so spray penetrant if stuck. Pull the housing off carefully. Coolant leftover drips, so pan ready. The thermostat sits inside with an O-ring seal.

Pull the old thermostat out. Note its orientation, spring side toward engine usually. Check for damage like stuck valve or corroded parts. Clean the housing and engine mating surfaces with a scraper and rag. Get every bit of old gasket off for a good seal.

Inspect the housing for cracks too. If bad, replace the whole thing. This cleaning step is crucial, skips lead to leaks later.

- Bolts removed evenly

- Old thermostat extracted

- Surfaces cleaned spotless

Install the New Thermostat

Grab your new thermostat. Place the bleed valve or jiggle pin at the 12 o’clock position for air escape. Fit the new O-ring or gasket, light grease helps seat it. Drop the thermostat into the engine recess, spring toward engine.

Position the housing over it. Thread bolts by hand first to avoid cross-threading. Tighten them snug, around 10-12 ft-lbs if you have a torque wrench, or just firm with your ratchet. Reconnect any heater tubes or brackets you moved.

Double-check everything aligns. A crooked install causes leaks or poor flow. Take a breath, you’re almost done with the hard part.

- Bleed valve at top

- New seal in place

- Bolts tightened properly

Refill Coolant and Test the System

Reconnect hoses and clamps tight. Pour fresh coolant into the radiator slowly. Fill the reservoir too. Start the engine and let it idle. Watch for leaks around the housing. As it warms, coolant level drops, so top off.

Burp the system by squeezing upper hoses or running with cap off until bubbles stop. Fans should kick on. Drive gently and monitor the gauge. No overheating means success. Recycle old coolant properly.

If issues pop, check for air pockets or wrong install. A good bleed fixes most. Enjoy the cool run.

- System filled slowly

- Air burped out

- No leaks spotted

Final Thoughts

Swapping the thermostat on your 2005 Chrysler 300 keeps the engine happy and prevents costly damage from overheating. With basic tools and care, you save hundreds over shop prices. Drive confident knowing you fixed it yourself. Next time the gauge creeps, you’ll handle it no sweat. Stay cool out there.

| Tool/Part | Description | Why You Need It | Approximate Cost |

|---|---|---|---|

| Socket Set | 10mm, 13mm with extensions | Remove housing bolts in tight spots | $20-50 |

| Pliers | Hose clamp pliers | Safely remove and reinstall hoses | $10-20 |

| Drain Pan | Large capacity bucket | Catch and reuse or dispose coolant | $10 |

| New Thermostat | 203°F OEM spec | Replaces faulty one for proper temp control | $15-30 |

| Gasket/O-ring | Fresh seal | Prevents leaks at housing | $5-10 |

| Coolant | HOAT orange type, 50/50 mix | Refill system properly | $15/gallon |

| Scraper/Rags | Plastic scraper and shop towels | Clean old gasket material thoroughly | $5 |

| Torque Wrench | Optional for precise tightening | Ensures bolts are snug without stripping | $30-60 |

Frequently Asked Questions (FAQs)

Is it hard to change the thermostat on a 2005 Chrysler 300 myself?

Not really, if you take your time. The location down low makes access tricky, especially on V6 models where you might need to remove the wheel for room. However, with basic tools and following steps carefully, most folks pull it off in a few hours. Just watch for spills and clean surfaces well. For example, my first time took longer because I fought a stuck bolt, but now it’s straightforward.

Can I drive with a bad thermostat in my Chrysler 300?

You can for short distances, but it’s risky. A stuck closed one causes quick overheating and potential engine damage like warped heads. Stuck open means poor heat and worse mileage. Better to fix it soon. One time, I drove a few miles to get home, but steam poured out, lesson learned.

Do I need to replace the housing when changing the thermostat?

Not always, only if it’s cracked or leaking. Inspect closely during removal. Many just swap the thermostat and seal. But on older 300s, corrosion eats housings, so grabbing a new one avoids future headaches. For instance, replacing both together ensures a solid seal long-term.

Is bleeding the cooling system necessary after this job?

Absolutely, to get rid of air pockets. Air traps cause hot spots and fake overheating. Run the engine with cap off, squeeze hoses, and top off coolant as it burps bubbles. Add a funnel for easier filling. Skipping this leads to gauge spikes even with a good thermostat.

Can a wrong thermostat cause problems in the 2005 model?

Yes, big time. Use the 203-degree one spec’d for it. Lower temp opens too soon, hurting efficiency. Higher might overheat. Orientation matters too, wrong way blocks flow. Always match OEM rating. I’ve seen cars run cold from cheap mismatches.

Do I have to drain all the coolant for this?

No, just enough to drop below the housing level. Saves time and coolant if it’s still good. Open the petcock and catch what comes. However, if coolant looks rusty, flush the whole system while you’re in there. Reusing clean stuff works fine.

Is the thermostat location different by engine size?

Yeah, a bit. On 2.7L and 3.5L V6, it’s low front left near the pump. 5.7L Hemi has it easier up top. Follow the lower hose always. V6 needs more access tricks like wheel removal. Knowing your engine helps plan.

Can I reuse the old gasket or O-ring?

Better not. Old ones harden and leak easily. A new seal costs little and guarantees no drips. Cleaning old residue is key anyway. Reusing often bites back with slow leaks that overheat later. Always fresh for peace of mind.