You’re cruising down the road and suddenly, turning the wheel feels like wrestling a giant. That whining sound from under the hood? Yeah, that’s your power steering pump crying for help. It happens at the worst time, right? But don’t sweat it.

Changing the pump yourself is easier than you think. Grab a wrench, a bit of patience, and some confidence. You’ll save money and feel pretty proud when your steering feels smooth again.

Steps to Change Power Steering Pump 1998 Chevy C1500

Locate and Inspect the Power Steering Pump

First, open your hood and take a look at the engine. The power steering pump sits on the front of the engine, usually near the driver’s side. It has a pulley with a belt wrapped around it. Check for leaks or cracks in hoses. A worn pump often drips fluid or makes noise when the engine runs.

Look closely at the fluid level in the reservoir. Low fluid can mimic a broken pump. If it’s empty or dark, it’s time to replace it. Also, check the serpentine belt that drives the pump. If it’s loose, cracked, or glazed, replace it along with the pump. This avoids future headaches and keeps your steering smooth.

Make sure the vehicle is parked on level ground and the engine is cool. Working on a hot engine can burn you badly. Gather safety gear: gloves and eye protection. You’ll also need a drain pan to catch old fluid. These precautions make the job safer and less stressful.

Before removing anything, loosen the belt tension. Some Chevy C1500s have a spring-loaded tensioner. Others need a wrench to move the tensioner pulley. Releasing belt tension first prevents damage and makes the pump easier to remove. Always double-check everything before starting full removal.

- Locate pump near driver’s side front of engine

- Inspect for leaks, cracks, or noise

- Check fluid level and belt condition

- Park on level ground and cool engine

- Gather safety gear and drain pan

- Loosen belt tension before removal

Drain the Old Power Steering Fluid

Place a drain pan under the pump and remove the return line first. Fluid will spill, so keep rags handy. Open the reservoir cap to help it drain faster. Gravity does most of the work.

After the return line, disconnect the pressure line. These lines may have high-pressure fittings, so loosen carefully. Avoid forcing the fittings; they can strip easily. Catch all fluid in your pan to prevent a mess.

Once lines are off, pump fluid from the reservoir using a turkey baster or hand pump. This removes any remaining liquid and reduces spillage. It’s messy but necessary. Clean up spilled fluid immediately. Power steering fluid can damage paint and rubber parts.

Inspect the old fluid. Dark, dirty, or burnt-smelling fluid confirms it’s time for a new pump. Proper disposal is important. Take the fluid to a recycling center. Don’t pour it down drains or on soil.

- Place drain pan under pump

- Remove return line first, then pressure line

- Pump remaining fluid from reservoir

- Clean spills immediately

- Inspect fluid for contamination

- Dispose of old fluid responsibly

Remove the Old Power Steering Pump

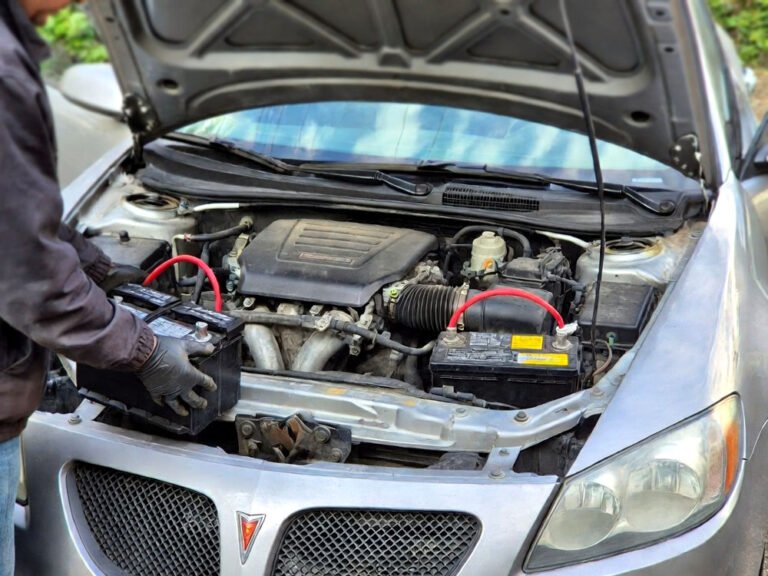

With lines off, remove the mounting bolts holding the pump to the engine. Keep track of each bolt. Some may be different lengths. Using a magnetic tray helps prevent loss.

Check the pulley before removing the pump. Some pulleys require a special puller tool. Others come off with simple wrenches. Don’t force it. Damaging the pulley means buying a new one.

Once bolts and pulley are removed, gently lift the pump out of the engine bay. It may feel heavy, so use both hands. Be careful not to damage surrounding hoses or components. Keep the workspace organized to avoid losing parts.

Clean the area where the pump sits. Remove dirt and grime with a rag. This ensures the new pump seats properly. Inspect mounting brackets for damage or wear. Any issues should be fixed before installing the new pump.

- Remove mounting bolts carefully

- Use proper tool for pulley removal

- Lift pump carefully from engine

- Avoid damaging surrounding parts

- Clean mounting area before new pump

- Inspect brackets for wear or damage

Install the New Power Steering Pump

Place the new pump into the mounting spot carefully. Align it with the bracket holes. Start threading bolts by hand. This prevents cross-threading. Tighten them securely with a wrench once all are in place.

Attach the pulley if it wasn’t pre-installed. Ensure it spins freely by hand before putting the belt back. Misalignment can cause belt wear and noise. Double-check that the pulley is seated correctly.

Reconnect pressure and return lines. Use new O-rings if the pump came with them. Tighten fittings carefully but firmly. Avoid overtightening; it can crack the line or fitting. Check each connection twice.

Reinstall the belt and adjust tension. Follow your vehicle’s manual for proper tension. Too loose or too tight can cause noise or damage. Spin the pulley by hand to ensure smooth movement before starting the engine.

- Place new pump and align bolts

- Attach pulley and check alignment

- Reconnect pressure and return lines

- Use new O-rings if available

- Reinstall and tension the belt correctly

- Verify smooth pulley movement

Refill and Bleed the Power Steering System

Fill the reservoir with fresh power steering fluid. Use the type recommended in your owner’s manual. Don’t overfill; check the marks on the reservoir.

Start the engine but don’t move the vehicle. Turn the steering wheel from lock to lock slowly several times. This forces air out of the lines and pump. Check the fluid level again and add if needed.

Inspect all connections for leaks while the engine runs. Listen for whining or unusual noise. These are signs of trapped air or loose fittings. Repeat the bleeding process if necessary.

After bleeding, drive the vehicle slowly and make turns to ensure smooth steering. Check fluid level again after the first drive. Adjust as needed. Proper bleeding prevents pump damage and ensures long-lasting performance.

- Fill reservoir with recommended fluid

- Turn steering wheel slowly lock-to-lock

- Check connections for leaks

- Listen for whining or noise

- Repeat bleeding if needed

- Test drive and recheck fluid

Final Checks and Maintenance Tips

After installation, clean any spilled fluid around the engine. Residue can attract dirt and cause problems later. Keep a rag nearby for future top-offs.

Monitor fluid levels weekly for the first few weeks. New pumps can lose small amounts of fluid initially. Catching drops early avoids bigger issues.

Listen for unusual noises during turns. Whining or squealing could indicate belt or pump problems. Address problems immediately to prevent damage.

Maintain a regular service schedule. Check hoses, belts, and fluid regularly. Preventive care prolongs pump life and keeps steering smooth. A little attention now saves money later.

- Clean spills around engine

- Monitor fluid levels weekly

- Listen for unusual noises

- Address problems immediately

- Regularly check hoses, belts, and fluid

- Maintain preventive care for pump longevity

Final Thoughts

Changing the power steering pump on a 1998 Chevy C1500 is manageable. With basic tools, patience, and care, anyone can do it. Following these steps ensures smooth steering and avoids leaks or damage. Stay safe, check everything twice, and enjoy your ride. The reward of saving money and learning car repair is worth the effort.

| Task | Key Tips | Tools Needed | Signs of Issue | Fluid Type |

|---|---|---|---|---|

| Locate pump | Inspect for leaks | Wrenches, gloves | Dripping fluid | Power steering fluid |

| Drain fluid | Use pan, open cap | Drain pan, rags | Dark or burnt fluid | Recommended type |

| Remove pump | Track bolts, clean area | Pulley tool, wrenches | Loose or damaged bolts | N/A |

| Install pump | Align bolts, check pulley | Wrenches, O-rings | Misaligned pulley | N/A |

| Refill & bleed | Turn wheel slowly | Fluid, rag | Whining noise | Correct fluid |

| Final checks | Monitor leaks, noise | Rag | Unusual sound | N/A |

Frequently Asked Questions (FAQs)

Is it difficult to change a power steering pump myself?

Changing a power steering pump can seem intimidating at first, but it’s very doable with basic tools. For a 1998 Chevy C1500, the steps are straightforward. The hardest part might be removing the pulley, depending on your model. With patience, careful work, and following instructions, most beginners can handle it. Take your time and organize parts properly. Safety gear, a drain pan, and a clear workspace make the job easier. You’ll gain confidence and save a lot on repair costs.

Can I drive with a failing power steering pump?

You technically can, but it’s not safe. A failing pump makes steering heavy and unpredictable, especially at low speeds. You may hear whining, see leaks, or feel jerky steering. Driving like this strains the steering system and could lead to total failure. Replacing the pump promptly prevents accidents and protects other parts. If you notice fluid loss or unusual noise, stop driving and fix the issue. The risk isn’t worth it.

Do I need special tools for a Chevy C1500 pump?

Most tools needed are standard: wrenches, a drain pan, and safety gear. Some models may require a pulley puller to remove the old pump. Otherwise, bolts and fittings are accessible with basic hand tools. Always check your specific vehicle manual. Using the right tool avoids damage and makes the job faster. Investing in a small tool kit is useful for future repairs too.

Is power steering fluid the same for all vehicles?

No, each vehicle has a recommended type. For a 1998 Chevy C1500, use the manufacturer-specified fluid. Using the wrong type can cause foaming, leaks, or pump damage. Always check the owner’s manual before filling. If unsure, buy fluid labeled for GM vehicles. Correct fluid ensures smooth steering and protects the system.

Can I reuse the old hoses with a new pump?

Sometimes hoses are fine, but inspect them carefully. Look for cracks, leaks, or soft spots. Reusing damaged hoses risks leaks and pump failure. If the hoses show wear, replace them during pump installation. New hoses ensure a proper seal and longer-lasting repair. It’s a small investment compared to repeating the job later.

Do I have to bleed the system after installation?

Yes, bleeding is crucial. Air trapped in the system can cause whining, jerky steering, or pump damage. Turn the wheel lock-to-lock several times with the engine running. Check fluid level and repeat if needed. Proper bleeding ensures smooth steering and avoids premature pump wear.

Can I save money by not replacing the pulley?

It depends on the pulley condition. If it’s damaged, misaligned, or worn, reuse can cause belt noise or pump failure. Inspect it carefully. Sometimes a new pulley is cheap and saves future trouble. Proper alignment is key for longevity and performance.

Is it necessary to check belt tension after pump replacement?

Absolutely. Incorrect belt tension can damage the pump or cause squealing. Tighten according to the manual and spin the pulley by hand to check smooth rotation. Correct tension keeps the pump and engine running efficiently. Always double-check before driving.