The first time I dealt with a stuck spark plug, it was a quiet Sunday morning that turned loud with frustration. The wrench refused to move, my knuckles kissed metal, and doubt crept in fast. A stuck spark plug feels personal, like the engine is testing your patience. The good news is this problem has patterns, and once you see them, removing a stuck spark plug becomes far less scary and far more doable.

Understanding Why Spark Plugs Get Stuck

A stuck spark plug usually is not about bad luck. It is about time, heat, and tiny chemical reactions working quietly against you. Engines heat up and cool down thousands of times, and during that cycle, metals expand and contract.

Over years, this movement can cause the spark plug threads to bind to the cylinder head. Aluminum heads are especially sensitive because aluminum reacts faster than steel, and most spark plugs are steel. I learned this the hard way on an old pickup that sat unused for a decade, baking in summer heat and freezing through winters.

Carbon buildup also plays a role. When engines burn fuel, small deposits form around the spark plug threads. Those deposits harden with heat and act like glue. Add moisture from humidity or washing the engine bay, and corrosion slowly creeps in. It does not happen overnight, which is why the plug feels fine until the day it does not move at all. That surprise resistance is what scares most people.

Another overlooked reason is over tightening during the last installation. Many DIY repairs skip torque specs, relying on feel instead. That extra twist can stretch threads and make removal feel impossible later. I once found a plug installed so tight it squealed when I tried to loosen it, which is never a comforting sound.

Understanding these causes helps you slow down and respect the process. Rushing only increases the risk of snapping the plug, which turns a small job into a nightmare.

- Heat cycles cause metal binding

- Carbon and corrosion act like glue

- Over tightening worsens future removal

Prepping the Engine and Your Workspace

Before touching a stuck spark plug, preparation sets the tone for success. Always start with a cold engine. Heat makes aluminum softer and threads more fragile, which increases the chance of stripping. I usually wait overnight, even if the job tempts me earlier. That patience once saved me from pulling threads out of a cylinder head on a compact sedan.

Next, clean the area around the spark plug thoroughly. Dirt loves to hide in spark plug wells, and once the plug loosens, that debris can fall straight into the cylinder. Compressed air works best, but a soft brush and vacuum can do the job too. The goal is to see clean metal before you turn anything. This small habit prevents much bigger problems later.

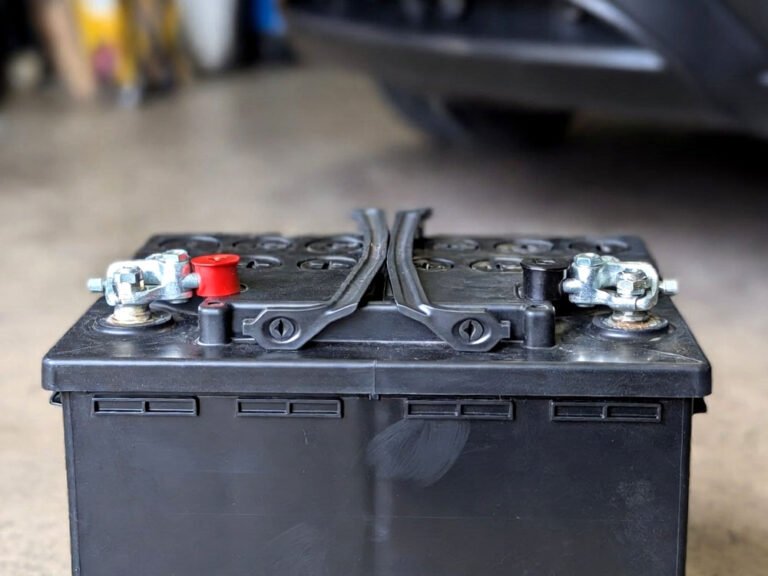

Your tools matter more than you think. Use a proper spark plug socket with a rubber insert, not a loose fitting deep socket. A long handled ratchet gives better control than brute force. Avoid impact tools completely. I once watched a friend crack a ceramic insulator using an impact gun, turning a simple tune up into an extraction job.

Finally, set your mindset. Expect resistance and accept that time is part of the process. Lay out penetrating oil, rags, and patience. When you feel calm and prepared, your hands naturally apply smoother pressure, and that alone reduces breakage risk.

- Work only on a cold engine

- Clean debris before loosening

- Use proper spark plug tools

Using Penetrating Oil the Right Way

Penetrating oil is not magic, but when used correctly, it feels close. The key is patience and placement. Spray or drip the oil directly where the spark plug meets the head, not just on top. Gravity helps here, so I often apply a little, wait, then apply again. On stubborn plugs, I let it soak for several hours or even overnight. The oil needs time to creep into the threads.

Choosing the right oil matters too. Dedicated penetrating oils work better than general lubricants. They are thinner and designed to break rust bonds. I once tried using regular engine oil out of impatience, and it did nothing except make my hands slippery. Lesson learned. Penetrating oil has a smell that tells you it means business.

While waiting, resist the urge to keep testing the plug. Constant movement can wipe away oil before it does its job. Instead, give it space and trust the chemistry. During one repair, I walked away, had dinner, and came back later to find the plug finally willing to move with gentle pressure. That moment feels oddly rewarding.

When you do return, wipe excess oil away so your socket seats fully. A slipping tool can round edges or crack porcelain. Clean contact plus well soaked threads is the sweet spot. This step often determines whether the plug comes out clean or fights you all the way.

- Apply oil at the thread base

- Allow hours for proper soaking

- Avoid repeated early twisting

Gentle Loosening Techniques That Actually Work

When it is time to loosen a stuck spark plug, think finesse, not force. Start by applying steady pressure in the loosening direction. If it does not move, stop. This pause prevents snapping the plug. A trick I use often is tightening the plug slightly first. That tiny movement can break carbon bonds and allow oil deeper into the threads. It feels counterintuitive, but it works surprisingly well.

Once you feel the slightest movement, reverse direction and loosen slowly. If resistance increases, stop again. Rocking the plug back and forth gently helps clean the threads as you go. Imagine unscrewing a rusty jar lid rather than breaking a bolt loose. Slow progress is still progress.

Listen and feel carefully. Smooth resistance is normal. Sharp squeaks or springy tension are warning signs. I once ignored that feeling and paid for it with a snapped plug body stuck in the head. Since then, I trust my hands more than my ego. If something feels wrong, it probably is.

Keep the socket straight at all times. Angled pressure stresses threads unevenly. If space is tight, use extensions rather than tilting the ratchet. Take breaks to reset your grip and calm your nerves. Removing a stuck spark plug is as much about patience as technique, and patience almost always wins.

- Tighten slightly before loosening

- Rock gently to clean threads

- Stop if resistance feels sharp

What to Do If the Plug Still Will Not Budge

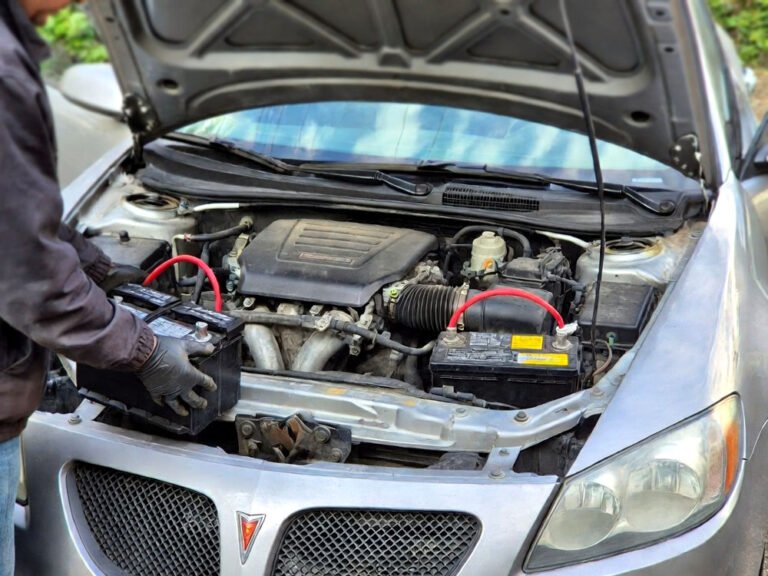

Sometimes, even after oil and patience, the spark plug refuses to move. This is the moment where many people panic or push harder. Do not. First, reapply penetrating oil and give it more time. Heat cycling can help here, but carefully. Briefly warming the engine, then letting it cool completely, can expand and contract metals just enough to loosen bonds. Never attempt removal while hot.

If the plug still will not turn, consider using a breaker bar only for controlled pressure, not sudden force. Slow, even torque gives you feedback through the tool. If the plug begins to turn and then tightens again, reverse direction and work it back. This cleaning motion protects threads from tearing.

There are specialty tools designed for broken spark plug extraction, but reaching for them too early often causes the break you are trying to avoid. I keep them as a last resort. When you feel real fear of snapping, it is okay to stop and reassess. There is no shame in knowing your limits.

At this stage, professional help can save money. A mechanic has experience, heat tools, and thread repair options if things go wrong. Walking away once saved me from turning a weekend job into a cylinder head replacement. Knowing when to stop is a skill every DIY mechanic needs.

- Use heat cycles cautiously

- Apply slow controlled torque

- Seek help before breaking parts

Preventing a Stuck Spark Plug Next Time

Once you finally remove a stuck spark plug, prevention becomes your new best friend. Always inspect the threads on both the plug and the head. Clean threads with a soft brush or thread chaser, never a cutting tap unless damage exists. Clean threads reduce friction and ensure accurate torque during installation.

Using a small amount of anti seize compound can help, but moderation is crucial. Too much changes torque readings and can cause over tightening. Many modern spark plugs come with special coatings, so check manufacturer recommendations first. I apply a thin smear only when advised, learned after overdoing it once and nearly stripping threads.

Proper torque is everything. Use a torque wrench and follow specifications exactly. Hand tight plus a guess is how problems begin. I keep a small torque wrench just for spark plugs, and it has paid for itself many times over. Consistency builds confidence.

Finally, regular maintenance matters. Removing and reinstalling plugs at proper intervals prevents long term bonding. Even if plugs are still good, breaking them free occasionally keeps threads healthy. Think of it like stretching stiff joints. A little routine care makes future removals smooth, predictable, and stress free.

- Clean threads before installing

- Use anti seize sparingly if allowed

- Torque correctly and maintain regularly

Final Thoughts

Learning how to remove a stuck spark plug is about slowing down and listening to the engine. With patience, the right tools, and respect for the process, you avoid expensive mistakes. Take your time, trust your hands, and remember that stopping early is often the smartest move.

Frequently Asked Questions (FAQs)

Is it safe to remove a stuck spark plug at home?

It is generally safe if you move slowly and understand the risks. Working on a cold engine, using penetrating oil, and applying gentle pressure reduce breakage. Many home mechanics succeed by respecting resistance and stopping early. However, if the plug feels brittle or squeals, professional help may be safer.

Can penetrating oil damage engine components?

Penetrating oil is safe when used properly. It evaporates and does not harm metal or seals in small amounts. The key is wiping excess oil away before removal. Avoid spraying excessively into the cylinder to keep things clean and controlled.

Do I need special tools for a stuck spark plug?

Basic tools like a spark plug socket, ratchet, and penetrating oil handle most cases. Specialty extractors are only needed if the plug breaks. Starting with simple tools helps you feel resistance clearly and avoid sudden force.

Is it normal for a spark plug to feel tight at first?

Yes, slight resistance is normal, especially on older engines. Smooth resistance usually means carbon buildup. Sharp or jerky resistance is not normal and signals potential breakage. Learning this difference protects your engine.

Can heat help loosen a stuck spark plug?

Heat cycling can help if done carefully. Briefly warming the engine, then letting it cool fully, allows metals to expand and contract. Never attempt removal on a hot engine because aluminum threads are vulnerable.

Do I need anti seize when reinstalling spark plugs?

It depends on the plug design and manufacturer. Some modern plugs have coatings that replace anti seize. If allowed, use only a very thin amount to avoid torque issues.

Is it okay to tighten a stuck spark plug before loosening?

Yes, slightly tightening can break carbon bonds. This trick often helps oil penetrate deeper. It should be gentle and controlled, never forced.

Can a mechanic really save a broken spark plug situation?

A skilled mechanic has extraction tools and experience that can prevent major damage. If you feel unsure, stopping early and seeking help often saves money and stress in the long run.